|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,EXW,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Model |

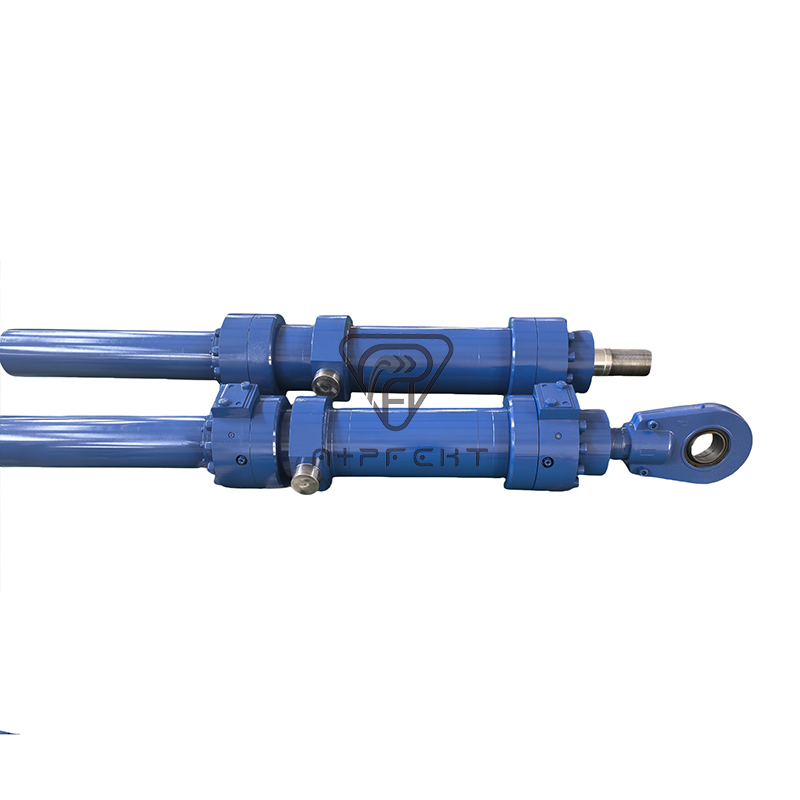

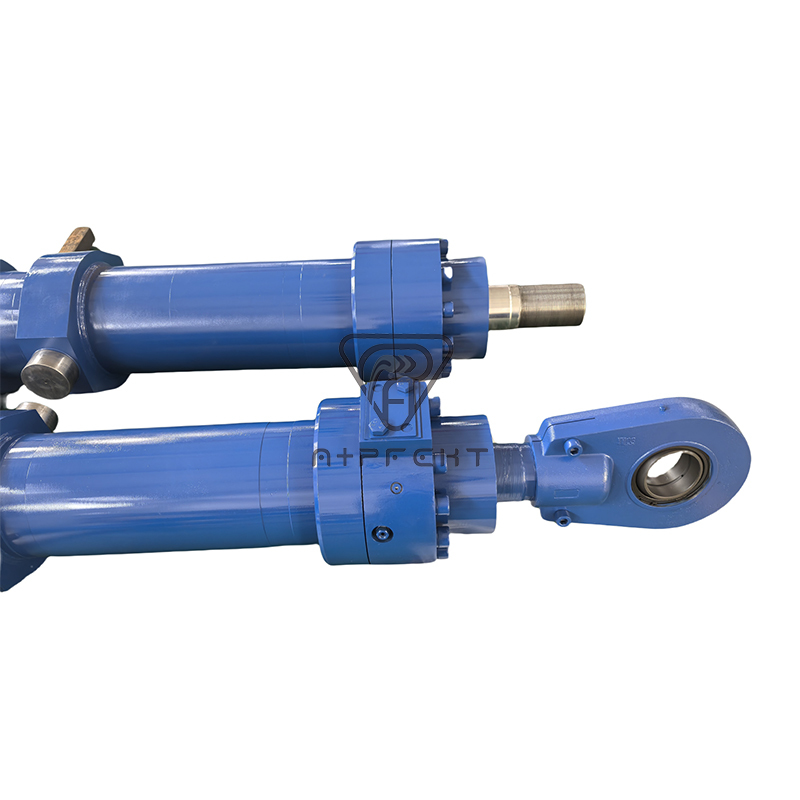

280 200-625 |

Hydraulic Cylinder for Excavator

Product Attributes

|

Model No. |

280 200-625 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Differential Hydraulic Cylinders: High-Performance Actuation for Industrial Precision

Engineered for dynamic force and speed control, differential hydraulic cylinders deliver superior performance in demanding industrial environments. By leveraging unequal piston areas, these advanced actuators enable dual-phase motion—rapid approach followed by high-force output—all from a single pressure source. This design eliminates the need for complex valve switching or additional components, making them ideal for space-constrained mobile equipment and automated production systems worldwide.

Key Features

● Two-speed operation without external valves: Fast movement during empty stroke, high thrust upon load engagement

● Integrated position sensing on both rod and piston sides for precise transition control

● Energy-efficient fluid recovery from rod side during extension, reducing pump flow demand by up to 40%

● Robust construction suitable for heavy-duty applications in manufacturing, logistics, and aerospace

● Compact footprint with enhanced power density—ideal for mobile machinery where weight and space are critical

Detailed Description

Differential hydraulic cylinders operate using a clever mechanical principle: when pressurized fluid enters the cap end (full piston area), the cylinder generates maximum force for pressing or lifting. When the same pressure is applied to the rod end (smaller effective area), it produces faster linear velocity due to reduced resistance. This allows seamless transitions between high-speed positioning and controlled force application—without changing system pressure or adding electronic controls. Modern versions incorporate closed-loop feedback mechanisms that monitor piston and rod positions in real time, ensuring accurate timing of each phase. Additionally, regenerative circuits capture return oil from the rod side during extension strokes, significantly lowering energy consumption and improving system efficiency. These cylinders are particularly valuable in industries requiring precision, repeatability, and reliability under variable loads. Their ability to provide two distinct motion profiles from one input makes them a preferred choice over traditional single-acting or double-acting designs in applications such as metal forming, packaging automation, and assembly processes.

Applications Across Industries

● Injection molding machines: Ejector systems benefit from rapid retraction followed by controlled ejection force

● Aircraft component assembly: Fixtures require consistent, repeatable clamping forces during composite bonding or fastening

● Railway wheel presses: Heavy-duty installations demand reliable, high-force press operations with minimal downtime

● Automotive manufacturing: Wheel hub pressing demands initial fast alignment then ultra-precise final assembly force

● Material handling: Forklift attachments move quickly when unloaded, automatically shifting to high-torque mode when loaded

● Industrial stapling systems: Provide quick actuation for feeding, then precise impact force for secure joining

User Feedback Highlights

Operators across global manufacturing sectors report improved cycle times and reduced maintenance costs after integrating differential cylinders into their hydraulic systems. One engineer noted, “The automatic shift between speed and force eliminated the need for manual valve changes in our press line—productivity increased by 15%.” Another user in the packaging industry added, “We now achieve tighter closure tolerances with less energy waste thanks to the built-in regenerative function.” These testimonials reflect widespread satisfaction with the technology’s simplicity, adaptability, and long-term cost-effectiveness.

English

English  Español

Español