|

Payment Type |

L/C,T/T,D/P |

|

Incoterm |

FOB,CIF,EXW,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Air,Land,Ocean |

|

Model |

160 100-258 |

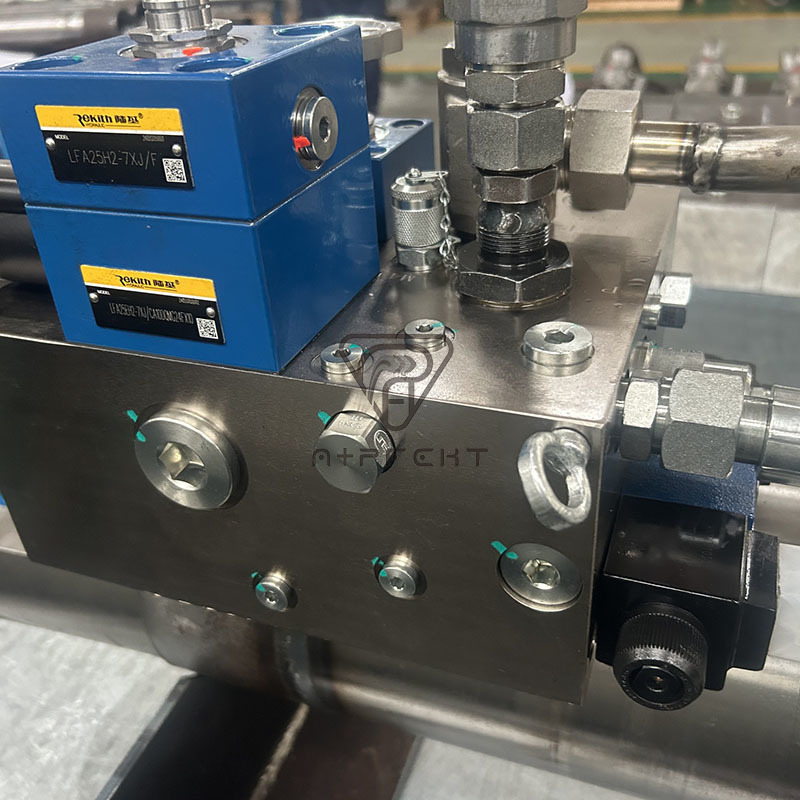

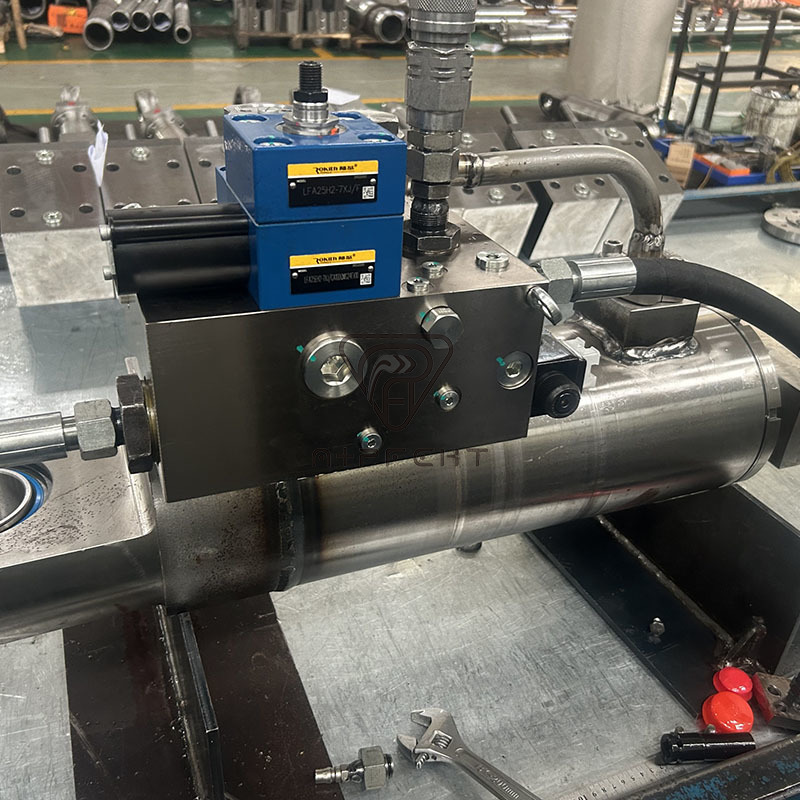

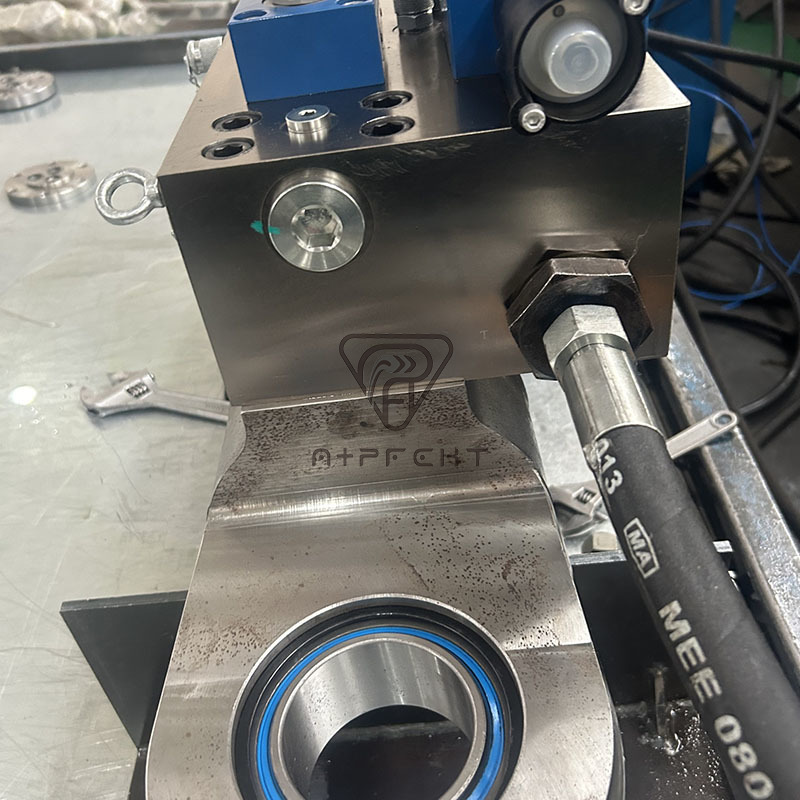

Heavy Duty Hydraulic Cylinder

Product Attributes

|

Model No. |

160 100-258 |

|

Brand |

NOK Hydraulic |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Industrial hydraulic cylinders deliver powerful linear motion for heavy machinery, engineered to withstand extreme operating conditions while maintaining precision. These robust actuators generate forces from 1 to 5,000 tons with positioning accuracy within ±0.1mm in servo-controlled models, featuring hardened steel construction and multi-stage sealing systems that endure millions of cycles. Their modular designs allow customized stroke lengths (up to 6 meters) and mounting configurations to fit diverse equipment layouts. Specialized versions include high-temperature models with 250°C-rated seals for foundry applications, and corrosion-resistant units with 316L stainless steel bodies for chemical processing plants.

Critical manufacturing applications include metal stamping presses requiring micron-level parallelism, injection molding machines with 3,000+ ton clamping force, and heavy-duty forging equipment that demands shock-resistant construction. Material handling systems utilize these cylinders for precise load positioning in automated warehouses, while steel mills employ water-cooled versions for continuous casting machine controls. The energy sector depends on their reliability for turbine blade adjustment mechanisms and oilfield blowout preventers.

Advanced features now incorporate IoT-enabled predictive maintenance through embedded sensors monitoring seal wear and fluid contamination. Their superior power density outperforms electromechanical alternatives in harsh environments, with vibration-resistant designs maintaining operation under 5g acceleration. The cylindersx27 ability to provide both precise control and extreme force makes them indispensable for industrial automation, where they synchronize multiple axes in production lines while withstanding around-the-clock operation.

English

English  Español

Español