|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

DDP,CIP,FOB,CFR,CIF,EXW |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Model |

200 125-600 |

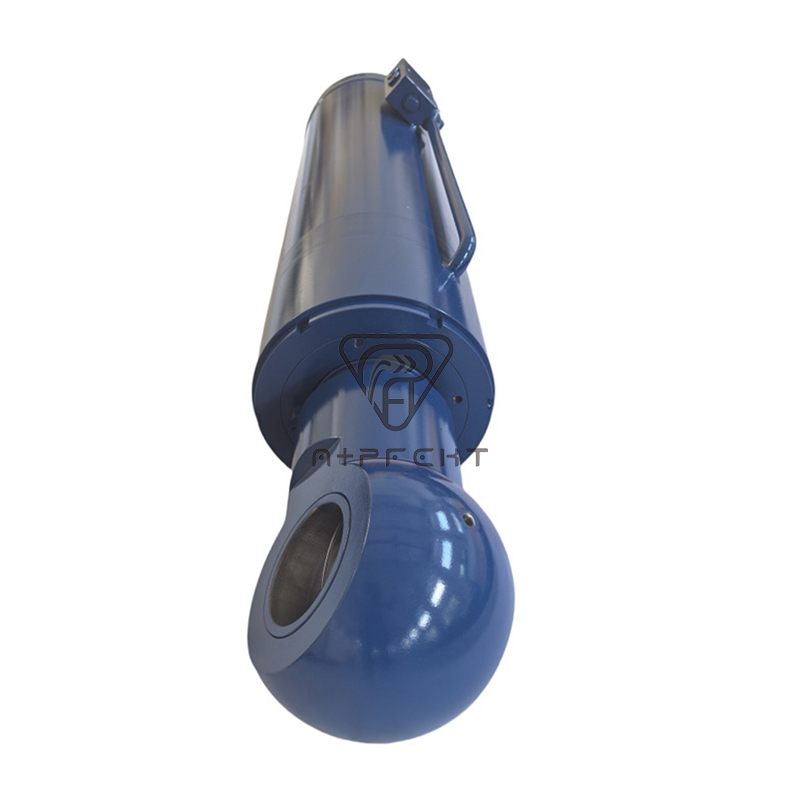

Large Oil Cylinders for Ships Marine Engineering

Product Attributes

|

Model No. |

200 125-600 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

|

Working Pressure |

24MPa |

|

Test Pressure |

36MPa |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Large hydraulic cylinders designed for metallurgical equipment play a crucial role in supporting the demanding operations of the steel, aluminum, and non-ferrous metal industries. These heavy-duty cylinders are engineered to endure extreme conditions such as high temperatures, intense pressures, and aggressive environments common in processes like forging, rolling, smelting, and casting.

A key advantage of metallurgical hydraulic cylinders is their exceptional strength and stability, which enables accurate control of heavy presses, continuous casting machines, ladle turrets, and rolling mill stands. Their advanced heat-resistant materials and specialized surface coatings provide superior protection against thermal deformation, scale build-up, and corrosion, ensuring reliable operation even during prolonged exposure to harsh production cycles.

Another benefit is their high precision and responsiveness, which are vital for maintaining tight tolerances and consistent product quality in automated metallurgical processes. These cylinders are often designed with integrated position sensing and advanced sealing systems to prevent oil leakage and contamination, reducing maintenance frequency and supporting uninterrupted production runs.

Applications include slab and billet handling, mold oscillation, ingot stripping, and the actuation of safety mechanisms. In summary, large hydraulic cylinders for metallurgical equipment deliver robust, precise, and long-lasting performance, making them indispensable for efficiency, safety, and productivity in modern metalworking facilities.

English

English  Español

Español