|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CFR,CIF,EXW,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Air |

|

Port |

Shanghai |

|

Model |

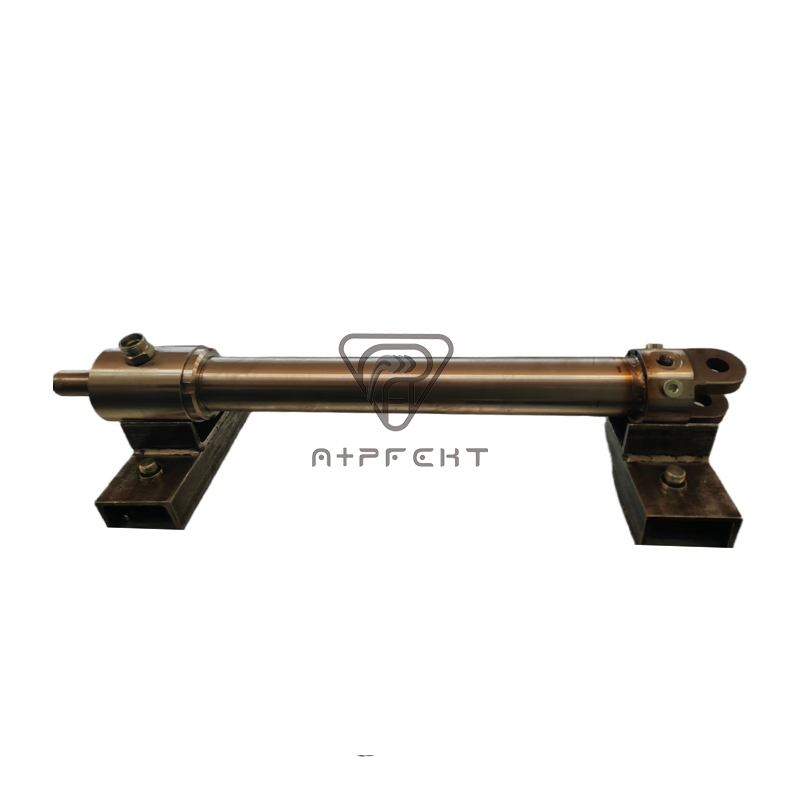

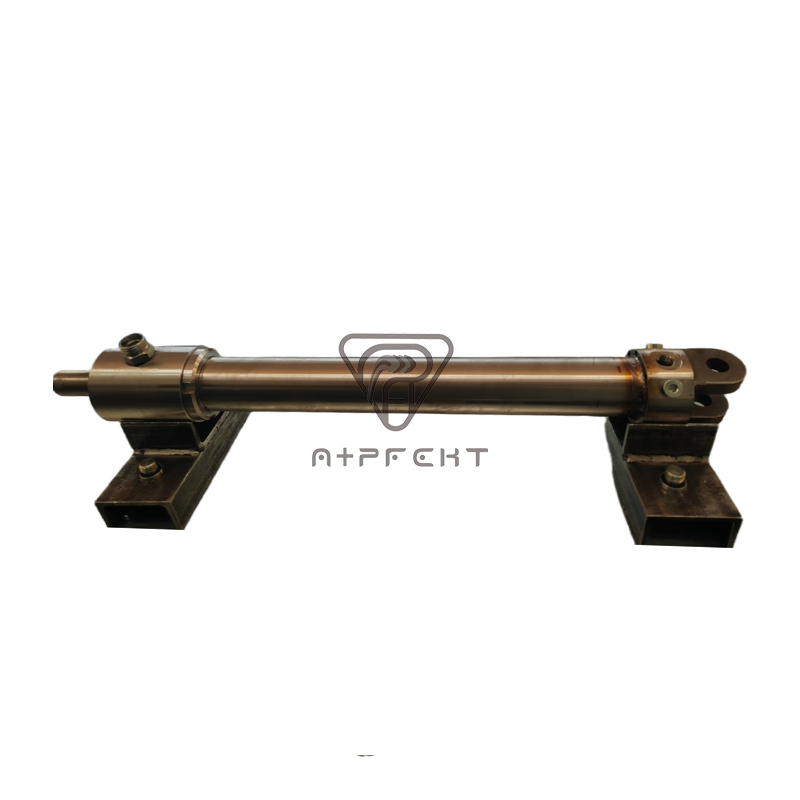

50 36-440 |

Anti-Corrosion Hydraulic Oil Cylinder

Product Attributes

|

Model No. |

50 36-440 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Stainless steel corrosion-resistant hydraulic cylinders are engineered for harsh environments where standard carbon steel components would fail. Constructed from 316L/304 stainless steel with 17-4PH precipitation-hardened rods, these actuators withstand continuous exposure to saltwater, chemicals, and acidic solutions while maintaining precise operation. The cylinders feature PTFE-encapsulated seals and Hastelloy fasteners for complete corrosion protection, achieving IP69K ratings for washdown applications in food/pharmaceutical processing. Special electropolished interior surfaces (Ra≤0.4μm) prevent particulate adhesion and bacterial growth in sterile environments. Marine-grade versions incorporate cathodic protection and duplex stainless steel construction for offshore drilling equipment enduring 10+ years in salt spray conditions.

These cylinders deliver 25-500kN forces with position repeatability of ±0.1mm, even when exposed to temperatures from -40°C to 150°C. Advanced models integrate ceramic-coated bearings and self-lubricating bushings to eliminate grease contamination in cleanrooms. The non-magnetic properties of stainless construction prevent interference with sensitive measurement systems in semiconductor equipment. Key applications include chemical injection systems in oil rigs requiring NACE MR0175 compliance, chlorine handling equipment in water treatment plants, and automated seafood processing lines with daily high-pressure sterilization. Their maintenance-free designs reduce downtime by 60% in corrosive environments compared to coated carbon steel cylinders, while the hygienic smooth surfaces meet FDA and EHEDG standards for direct product contact. The combination of corrosion immunity, cleanroom compatibility, and marine-grade durability makes these cylinders essential for critical operations where material integrity directly impacts safety and productivity.

English

English  Español

Español