|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,EXW,FCA,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Model |

140 90-170 |

Customized Tie-Rod Hydraulic Cylinder

Product Attributes

|

Model No. |

140 90-170 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

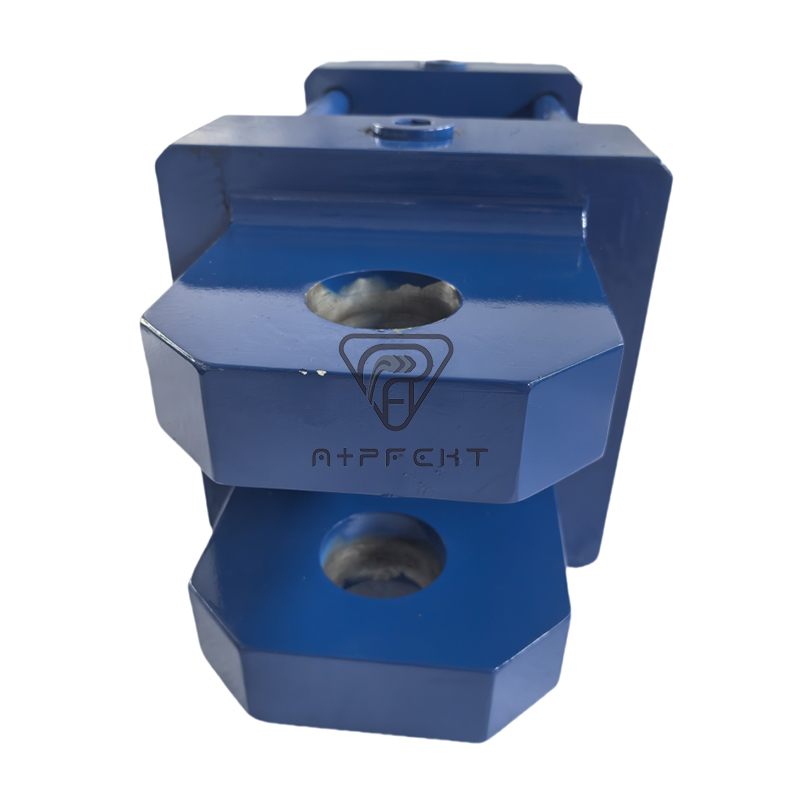

Tie-rod hydraulic cylinders excel in applications requiring frequent maintenance and modular flexibility across multiple industries. These versatile actuators dominate plastic injection molding machines, where their disassemblable design allows quick seal replacement during mold changes, with typical clamp forces reaching 3,000 tons in large-tonnage presses. The food processing industry relies on its stainless steel variants with polished surfaces (Ra<0.8μm) for hygienic packaging equipment that undergoes daily washdowns. In metal stamping operations, their standardized flange patterns enable fast die changeovers, while the through-rod versions provide balanced force distribution for precision blanking applications.

Material testing laboratories utilize these cylinders for fatigue testing rigs, benefiting from their ability to swap components between test configurations without specialized tools. The automotive sector employs them in robotic welding fixtures where the tie-rod structure absorbs vibration impacts better than welded designs. Semiconductor manufacturers value the cleanroom-compatible models with low-outgassing seals for wafer handling systems.

Specialized applications include:

● Theater stage lifts requiring quiet operation

● Hydraulic presses for powder metallurgy

● Paper mill roll positioning systems

● Wind turbine blade adjustment mechanisms

Modern iterations incorporate smart features like strain-gauge-equipped tie-rods for real-time load monitoring and quick-disconnect gland systems that reduce service time by 70%. Their modular nature facilitates custom stroke adaptations by simply adding intermediate spacers, making them ideal for prototype machinery and R&D applications. The cylindersx27' vibration-damping characteristics prove superior in pulsating applications like concrete compactors, while the standardized components inventory reduces downtime in global operations.

English

English  Español

Español