|

Payment Type |

T/T,L/C,D/P,Paypal |

|

Incoterm |

FOB,CIF,EXW,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Land,Air,Ocean |

|

Port |

shanghai |

|

Model |

250 160-650 |

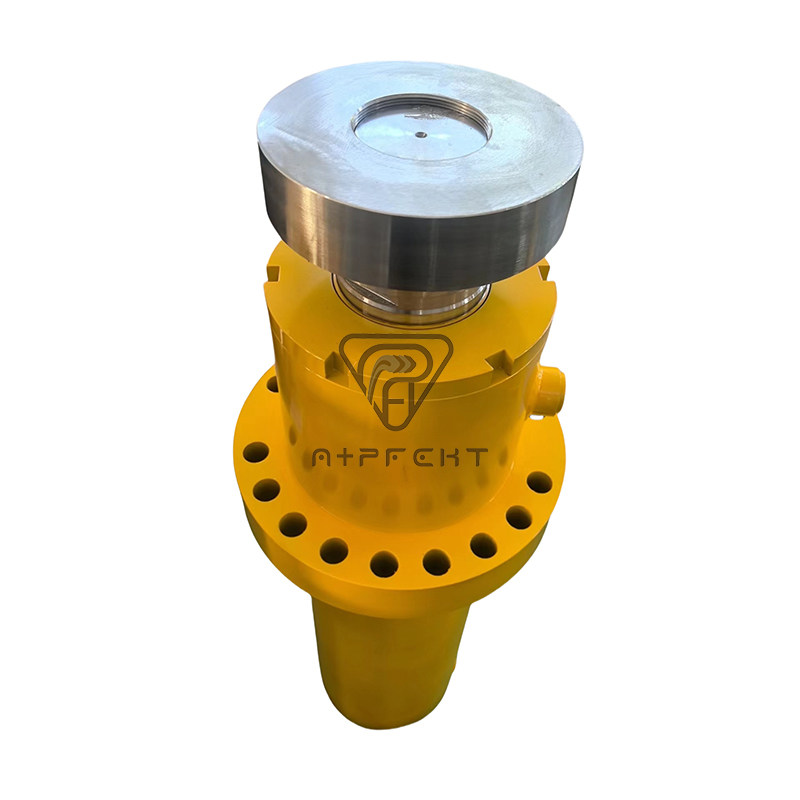

Vulcanizing Machine Hydraulic Cylinder

Product Attributes

|

Model No. |

250 160-650 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

|

Package Type |

Wooden package |

Hydraulic cylinders for vulcanizing presses deliver precise high-force compression essential for rubber curing and tire manufacturing, operating reliably in steam-filled environments up to 200°C continuous exposure. These robust actuators feature double-acting designs with 50-2,000 ton clamping force capacity, maintaining ±0.1mm parallelism across mold surfaces during the curing cycle. Specialized models incorporate rapid-return systems achieving <30 second cycle times for high-volume production, while PTFE-impregnated piston seals and stainless steel construction withstand constant steam exposure and chemical byproducts. The cylindersx27 precision guidance systems prevent mold misalignment, with integrated position sensors enabling closed-loop control of compression depth within ±0.5mm accuracy. Heavy-duty versions for tire presses utilize multi-stage telescopic designs to accommodate large daylight openings while generating uniform pressure distribution across the mold surface. Advanced thermal management systems include water-cooled piston rods and heat-reflective coatings to protect critical components from 180°C steam temperatures. These cylinders are fundamental to producing consistent vulcanized products, from automotive tires requiring 1,500+ ton molding pressure to technical rubber parts needing micron-level thickness control. Their fail-safe hydraulic circuits maintain pressure during power interruptions, while modular designs allow quick seal replacement without full disassembly - critical for minimizing downtime in 24/7 production environments. The combination of extreme temperature resistance, precision force control, and rapid cycling makes them indispensable for modern rubber processing lines where energy efficiency and product consistency directly impact profitability.

English

English  Español

Español