|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CFR,CIF,EXW,CPT,DDP,CIP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Land,Air,Ocean |

|

Model |

50 235-200 |

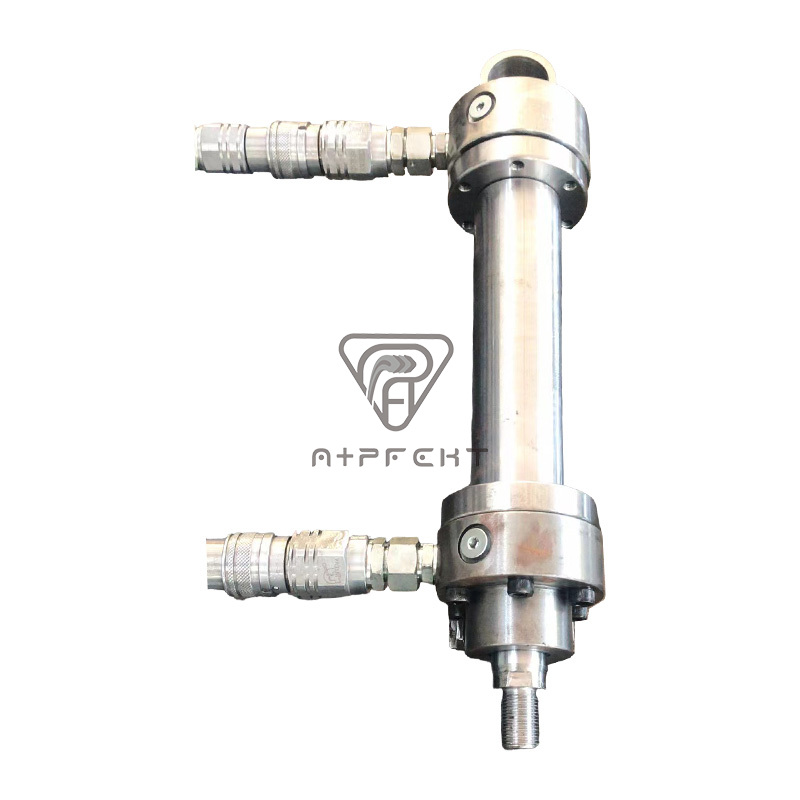

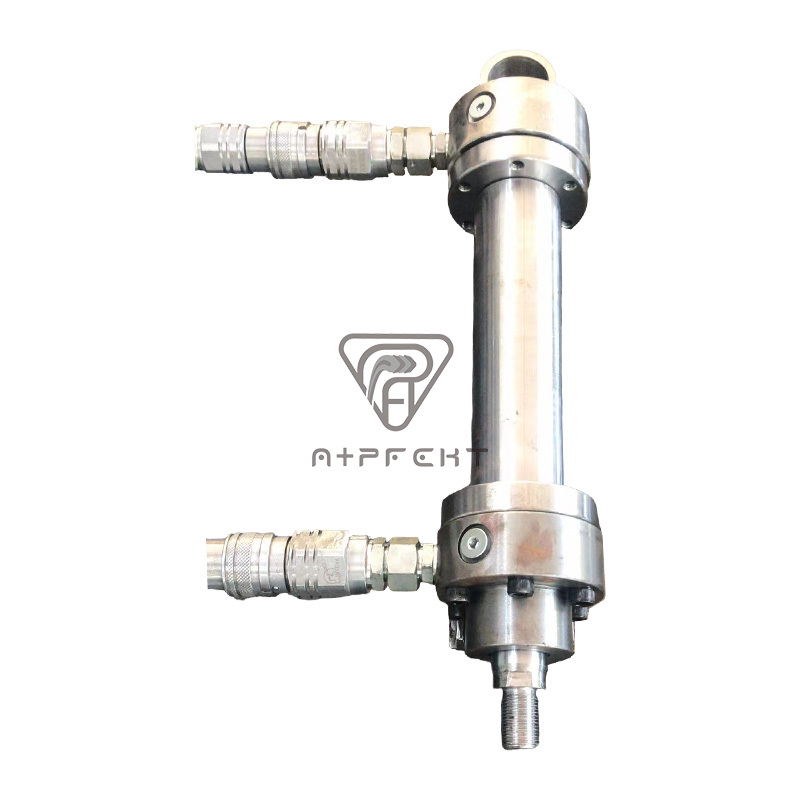

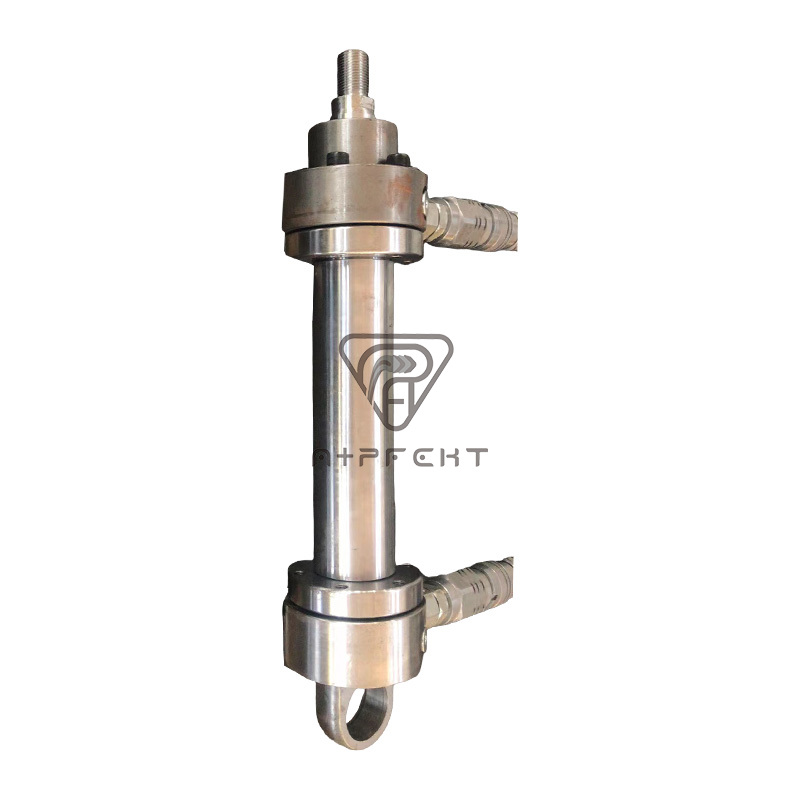

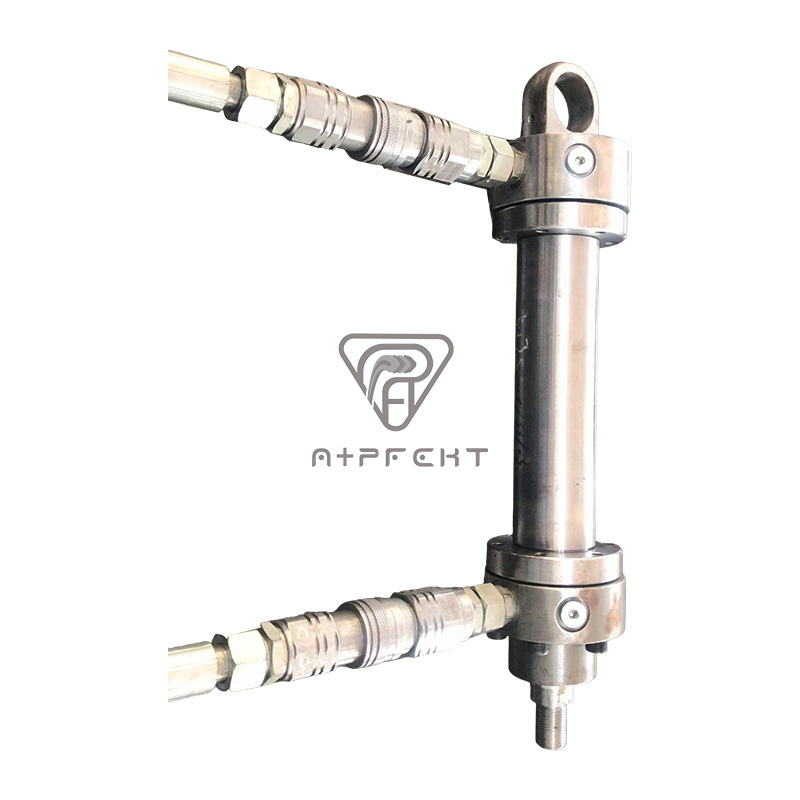

Flame Proof Hydraulic Actuator

Product Attributes

|

Model No. |

50 35-200 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

High-temperature hydraulic cylinders represent cutting-edge fluid power technology engineered for the most thermally demanding industrial processes. These specialized actuators incorporate revolutionary thermal management systems featuring nanotechnology-enhanced ceramic coatings that reduce heat transfer by 40% compared to conventional designs. The cylinders utilize advanced shape-memory alloy components that automatically adjust clearances based on temperature fluctuations, maintaining optimal performance from -50°C to 650°C. Their innovative cooling architecture employs microfluidic channels that circulate high-temperature synthetic oils, enabling continuous operation where water-cooled systems would fail.

These cylinders are transforming ultra-high-temperature manufacturing processes. In next-generation nuclear reactors, they precisely control control rod positioning in 550°C liquid sodium coolant environments. The aerospace industry employs them for hypersonic vehicle testing rigs that simulate re-entry conditions exceeding 600°C. Advanced materials processing utilizes their capabilities for graphene production systems, where they maintain precise pressure control in 500°C chemical vapor deposition chambers.

The latest models feature self-diagnosing thermal protection systems with AI-driven predictive algorithms that anticipate cooling needs before critical temperature thresholds are reached. Their graphene-enhanced composite seals demonstrate 10x longer service life than traditional designs in extreme heat cycling conditions. These technological breakthroughs enable previously impossible applications like direct molten salt handling in concentrated solar power plants and precision positioning in plasma arc waste treatment systems operating at 800°C.

English

English  Español

Español