|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CFR,CIF,EXW,CPT,DDP,CIP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Model |

80 56-90 |

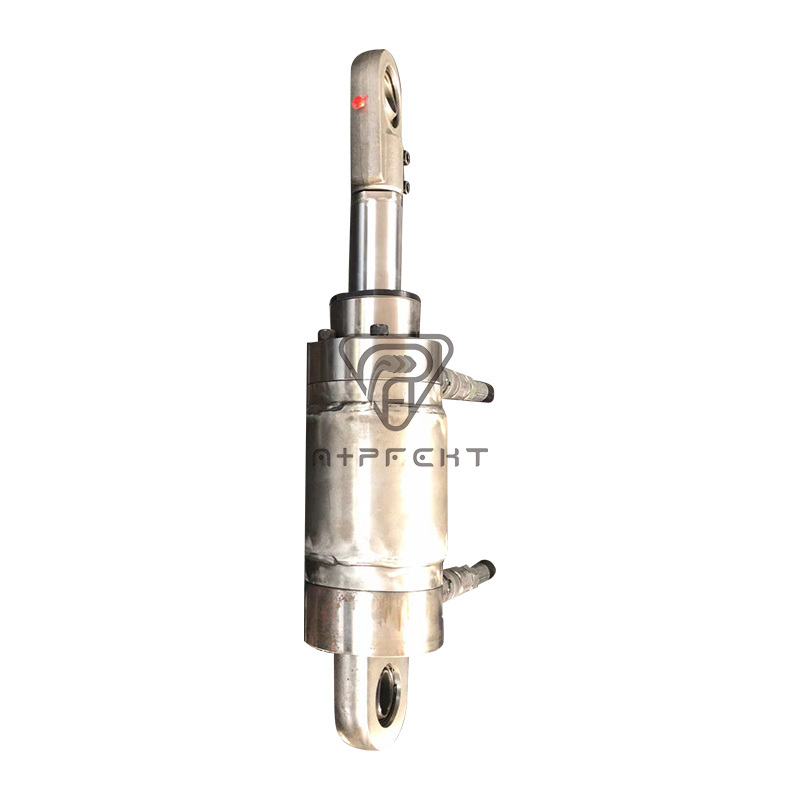

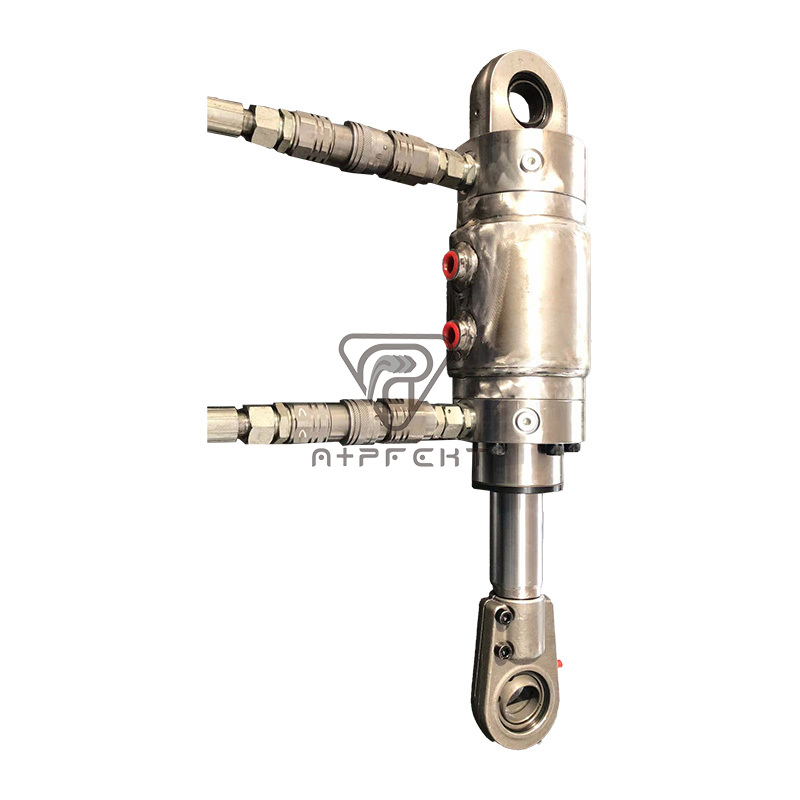

Furnace Grade Hydraulic Actuator

Product Attributes

|

Model No. |

80 56-90 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

High-temperature hydraulic cylinders are specifically engineered for extreme thermal environments, utilizing advanced materials and innovative cooling technologies to maintain reliable operation. These specialized actuators feature multi-layer thermal protection systems including ceramic-coated piston rods, refractory metal alloy components, and phase-change cooling channels that actively regulate surface temperatures. The cylinders incorporate self-lubricating graphite composite bearings and metal-encased seals that withstand continuous operation at 300°C+ while preventing fluid vaporization. Their reinforced structures compensate for thermal expansion differentials, maintaining precise alignment under rapid temperature fluctuations common in industrial heating processes.

Critical applications include die-casting machine platens where the cylinders endure direct contact with 700°C molten metal while providing 2,000+ ton clamping force with 0.05mm parallelism. Semiconductor manufacturing employs ultra-clean versions with vapor-deposited ceramic coatings for wafer handling in high-vacuum annealing furnaces. Power generation plants use them for boiler sootblower positioning, where they resist continuous exposure to 400°C flue gases and abrasive ash particles. Advanced designs now incorporate microchannel cooling systems that circulate specialized heat-transfer fluids, enabling operation nearer heat sources than conventional water-cooled models.

These cylinders prove essential in applications like aluminum extrusion presses, where they maintain precise billet containment despite die temperatures exceeding 500°C. Their ability to deliver consistent performance in thermally hostile environments while maintaining precision motion control makes them invaluable for high-temperature industrial processes where conventional hydraulics would rapidly degrade.

English

English  Español

Español