|

Payment Type |

L/C,T/T,Paypal |

|

Incoterm |

FOB,CIF,EXW |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

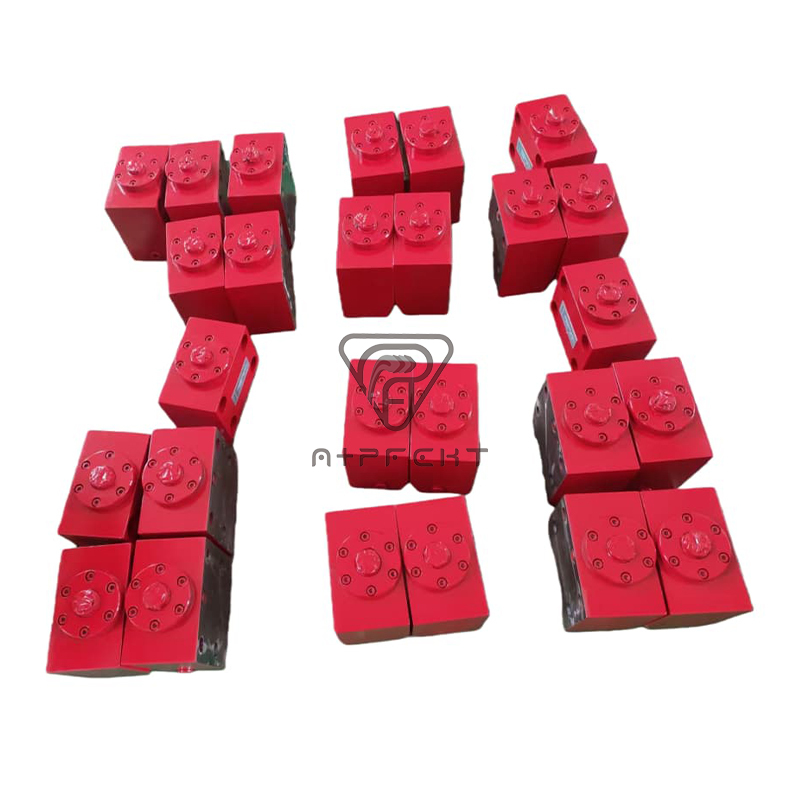

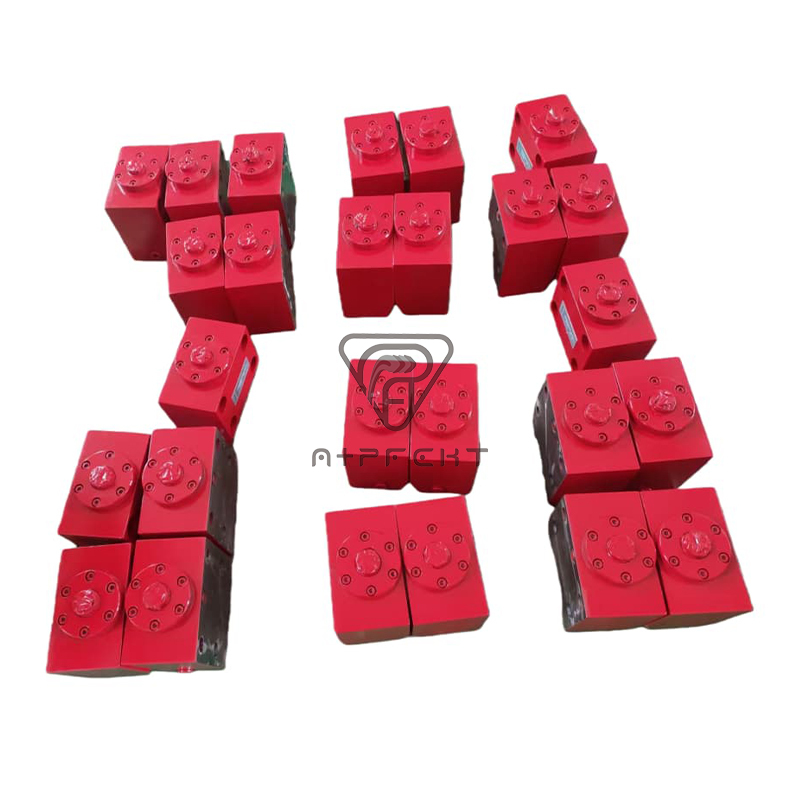

Custom Metallurgical Hydraulic Cylinders

Product Attributes

|

Model No. |

63 36-85 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Metallurgical hydraulic cylinder are integral to a wide range of heavy-duty processes in the steel and metalworking industries, where they provide reliable linear motion and force transmission under extreme conditions. These telescopic hydraulic cylinder are extensively used in continuous casting machines to control mold oscillation, strand guiding, and billet cutting mechanisms, ensuring precise shaping and separation of molten metal. In hot and cold rolling mills, they facilitate precise positioning of rolls and apply high-pressure force to adjust thickness during metal forming. They also play a critical role in forging presses, where they generate immense pressure to shape metal ingots or blanks under high-temperature conditions. Additionally, these double acting hydraulic cylinder are deployed in blast furnace systems for taphole drilling, slag removal, and charging operations, enduring exposure to intense heat and abrasive particles. In heat treatment furnaces, they enable controlled movement of quenching systems or load-bearing fixtures, maintaining dimensional accuracy during thermal cycling. Other applications include die casting machines, where they withstand repetitive impact loads during mold clamping and ejection, as well as scrap metal processing equipment like shears and balers, where they deliver consistent force for cutting and compacting metallic waste. Designed to operate in environments with elevated temperatures, corrosive atmospheres, and mechanical shock, these cylinders ensure operational stability and safety in processes such as ladle refining, electrode positioning in electric arc furnaces, and automated handling of red-hot workpieces. Their ability to maintain performance under cyclic stress and thermal fluctuations makes them indispensable for optimizing productivity and precision in modern metallurgical operations.

English

English  Español

Español