|

Payment Type |

L/C,T/T |

|

Incoterm |

FOB,CIF,EXW,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Land,Ocean,Air |

|

Port |

Shanghai,Guangzhou |

|

Model |

63 36-135 |

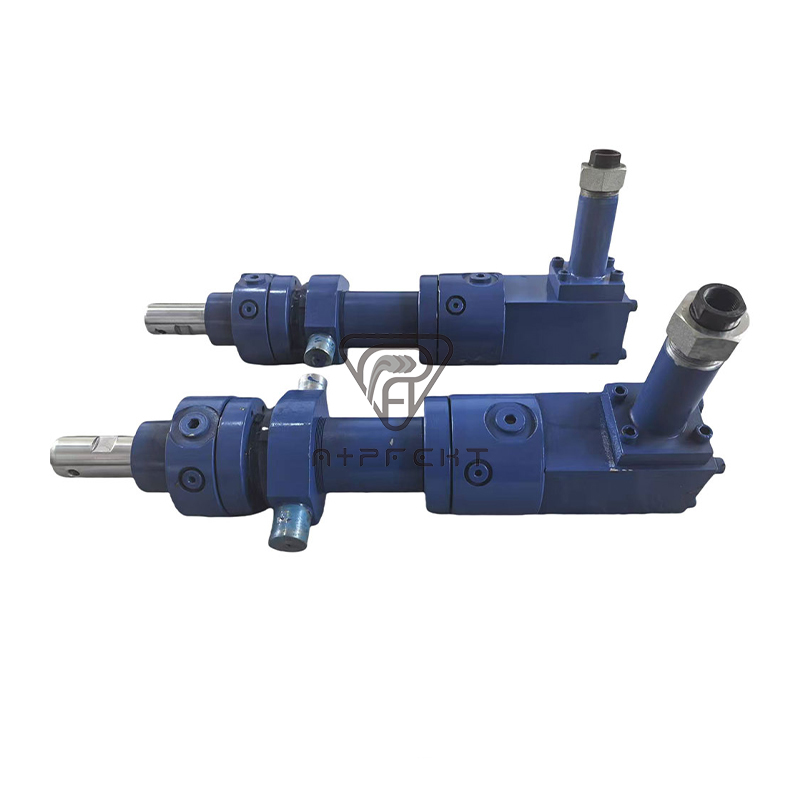

Hydraulic Ram Cylinder Oil Cyclinder

Product Attributes

|

Model No. |

63 36-135 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

|

Package Type |

Wooden package |

Hydraulic ram cylinder oil cyclinder are vital in an array of machines as they provide exceptional power, precision, and reliability. Industrial hydraulic oil cylinders main role in machines is transforming hydraulic energy into linear work, which can lift, push, and pull in a very efficient manner. One noticeable benefit of large hydraulic cylinders is their power-to-size ratio. Compact designs of construction equipment such as excavators and industrial presses are easily supercharged with these systems. These devices are built to last; robust construction, advanced sealing technologies, and other features ensures performance under extreme loads and harsh environmental conditions. Movements in hydraulic cylinder are smooth and provide high controllability in speed and force; this is paramount in precision tasks such as automation in manufacturing. Electric hydraulic oil cylinder are preferable to pneumatics as they provide a minimization to compressibility problems, which provides a more steady force. Hydraulics systems are also adjustable in a diverse manner, from aerospace to agriculture, through cylinder size, pressure, and mounting styles. Maintenance involves simply replacing batch components like seals. More so, with complex automated devices, hydraulic pumps and valves work together without clashes, necessitating no additional parts. From a long-term perspective, these systems are cost-effective as they are durable and can endure repetitive heavy-duty cycles.

English

English  Español

Español