|

Payment Type |

L/C,T/T,Paypal |

|

Incoterm |

FOB,CIF,EXW,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

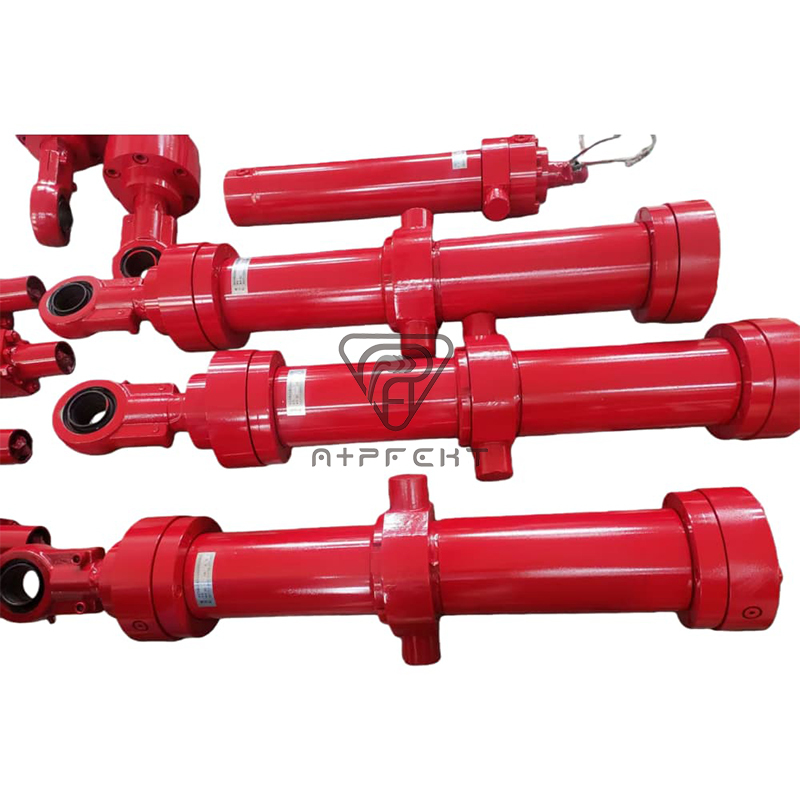

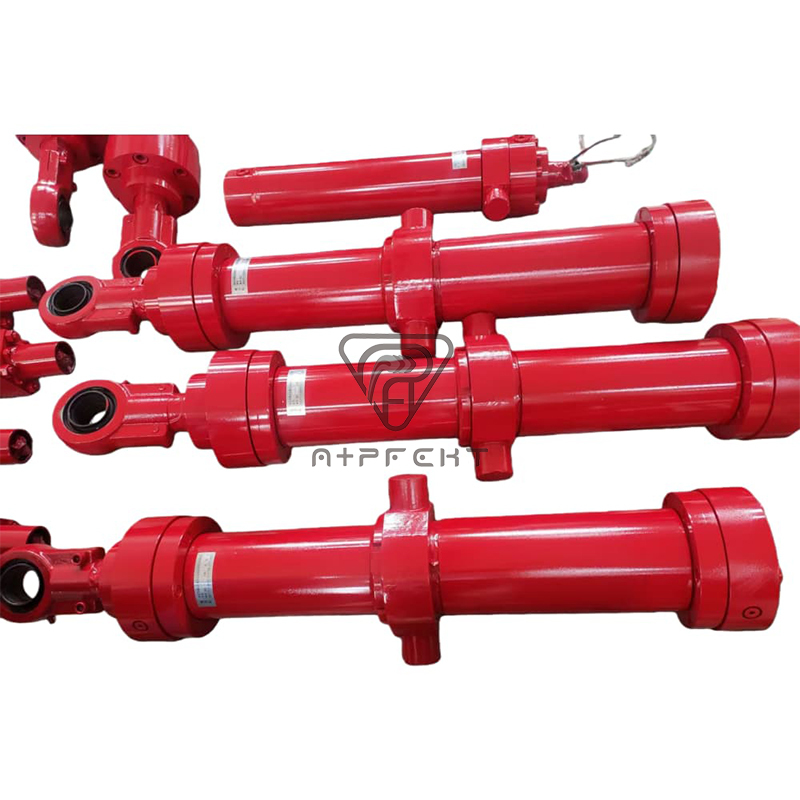

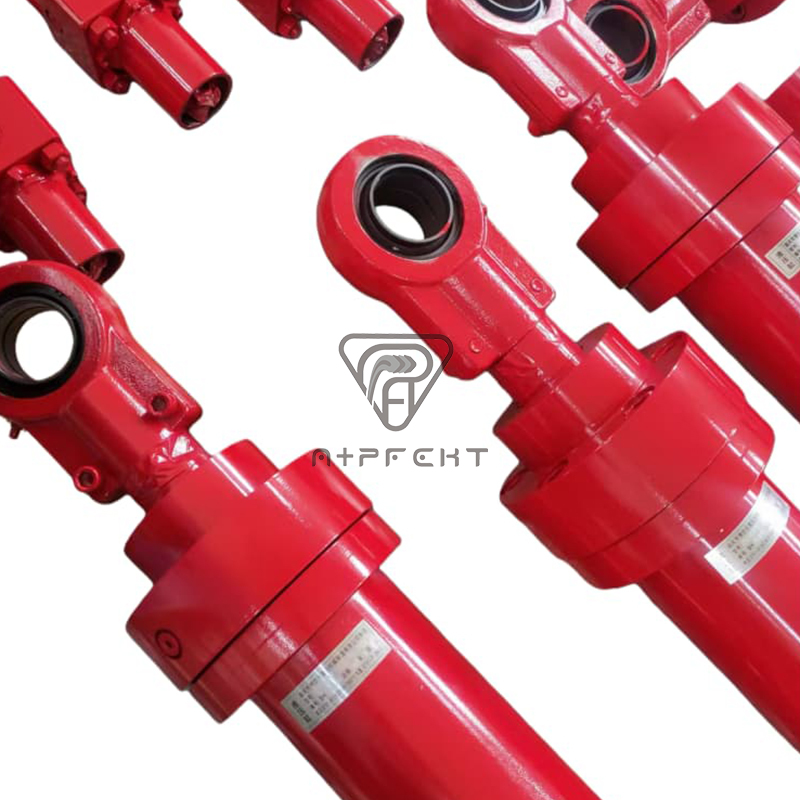

Telescopic Metallurgy Hydraulic Cylinder

Product Attributes

|

Model No. |

125 70-715 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Hydraulic Cylinder is the core executive component of hydraulic system, which converts hydraulic energy into mechanical energy of linear motion.

一、 Large Hydraulic Cylinders Basic principles and composition

1. Working principle: Based on Pascal's principle.

By applying pressure to the liquid inside a closed container, the pressure will be transmitted to all parts and walls of the container without any loss. In hydraulic cylinders, pressure oil acts on the effective area of the piston, generating a huge linear thrust or tension.

2. Basic structure: A typical hydraulic cylinder is mainly composed of the following components:

● Cylinder: The main container that bears oil pressure.

● Pistons: Divide the interior of the cylinder into two chambers (rod chamber and rodless chamber).

● Piston rod: connected to the piston, transmitting mechanical force.

● End caps: front and rear end caps, sealing both ends of the cylinder barrel.

● Seals: Key to preventing internal and external leakage, including piston seals, piston rod seals, guide sleeve seals, etc.

● Guide sleeve: supports and guides the piston rod to prevent eccentric wear.

● Buffer device: Reduce speed at the end of the stroke to prevent the piston from hitting the end cap.

● Exhaust device: Remove air mixed into the oil.

二、Industrial Hydraulic Oil Cylinders Core Technology and Performance Parameters

1、Sealing technology: It is the soul of hydraulic cylinders, determining their performance and lifespan.

● Sealing forms: O-ring, Y-ring, Glay ring, Steller seal, combination seal, etc.

● Requirements: High pressure resistance, high temperature resistance, wear resistance, low friction, good compatibility.

2、Buffer technology: prevents impact and noise at the end of the stroke.

● Principle: When the piston approaches the end cap, the oil in the return chamber can only be discharged through a small hole or throttle valve, forming back pressure and forcing the piston to decelerate.

English

English  Español

Español