|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CFR,CIF,EXW,CIP,DDP |

|

Min. Order |

1 Set/Sets |

|

Transportation |

Ocean,Land,Air |

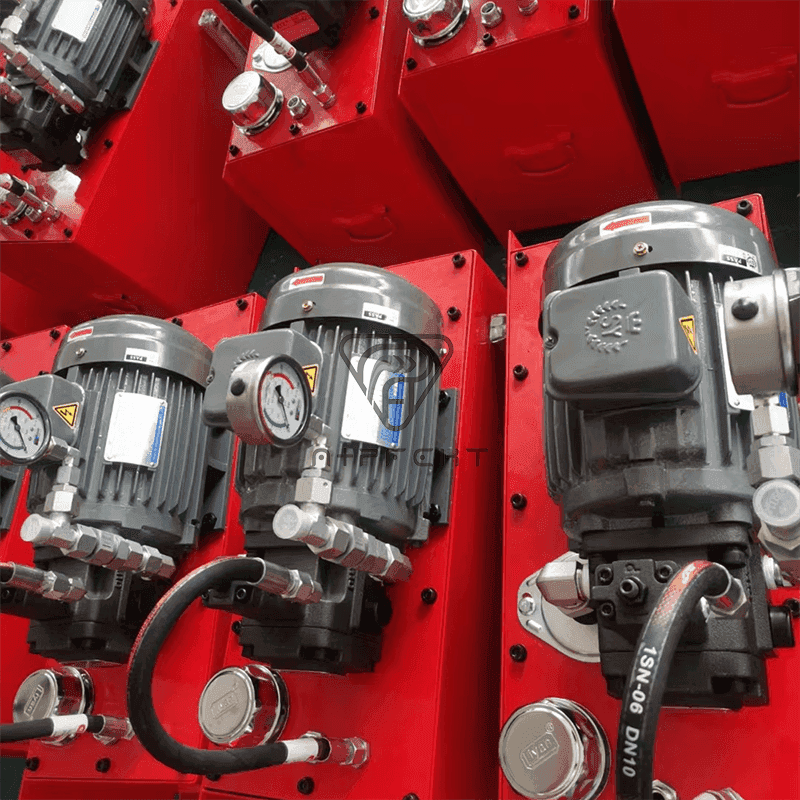

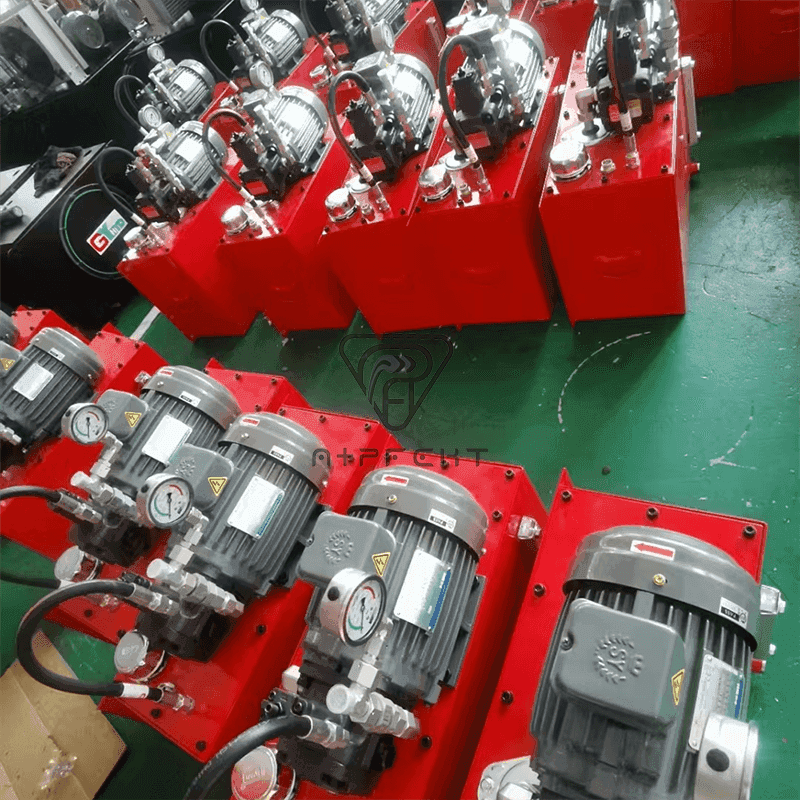

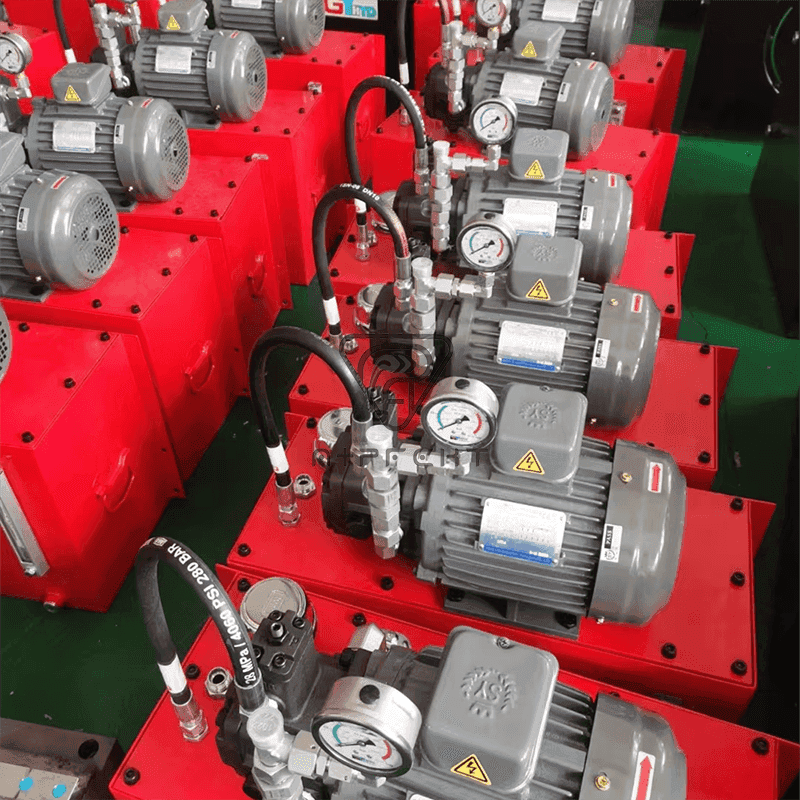

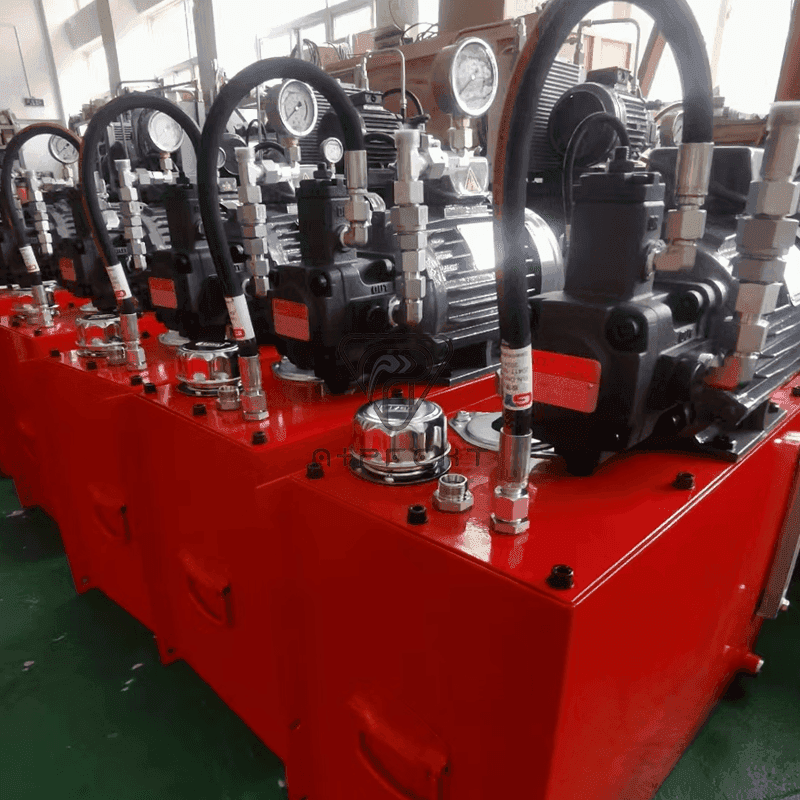

Hydraulic System of Grinding Machine

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Odm, Oem |

Packaging & Delivery

|

Selling Units |

Set/Sets |

Vertical cylinder honing machine hydraulic systems are precision-engineered for ultra-fine surface finishing applications, delivering exceptional control for bore machining operations. These specialized systems feature servo-controlled hydraulics that maintain consistent honing pressure within ±0.5 bar throughout the stroke, enabling surface finishes to Ra 0.1μm tolerance. The closed-loop design incorporates high-response proportional valves with 10ms adjustment capability to compensate for material variations during the honing process. Advanced filtration maintains ISO 4406 13/10 fluid cleanliness through multi-stage contamination control, while temperature stabilization systems keep oil viscosity within ±1% of optimal working range.

Critical applications include engine block cylinder finishing for automotive manufacturers, where the systemx27s adaptive pressure control accommodates varying material hardness across different engine components. The aerospace industry utilizes these systems for Hydraulic Actuator cylinder honing, where the precise pressure profiling ensures uniform wall thickness in high-strength alloy components. Heavy equipment manufacturers depend on them for final finishing of Hydraulic Cylinder bores in construction machinery, achieving the exacting tolerances required for high-pressure seal performance. Emerging applications include medical implant manufacturing, where the systemsx27 micro-adjustment capabilities enable nanometer-level surface finishing of titanium alloy components.

The latest generation systems incorporate AI-powered adaptive control that learns optimal honing parameters for different materials, reducing setup times by 60%. Integrated vibration analysis sensors detect tool wear in real-time, while energy-recovery circuits capture and reuse 30% of the hydraulic energy during stroke reversal. These technological advancements make vertical honing machine hydraulic systems indispensable for precision manufacturing applications where surface finish quality directly impacts product performance and longevity.

English

English  Español

Español