|

Payment Type |

D/P,T/T,L/C,D/A |

|

Incoterm |

FOB,CFR,CIF,EXW,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Model |

40 22.4-215 40 22.4-215 |

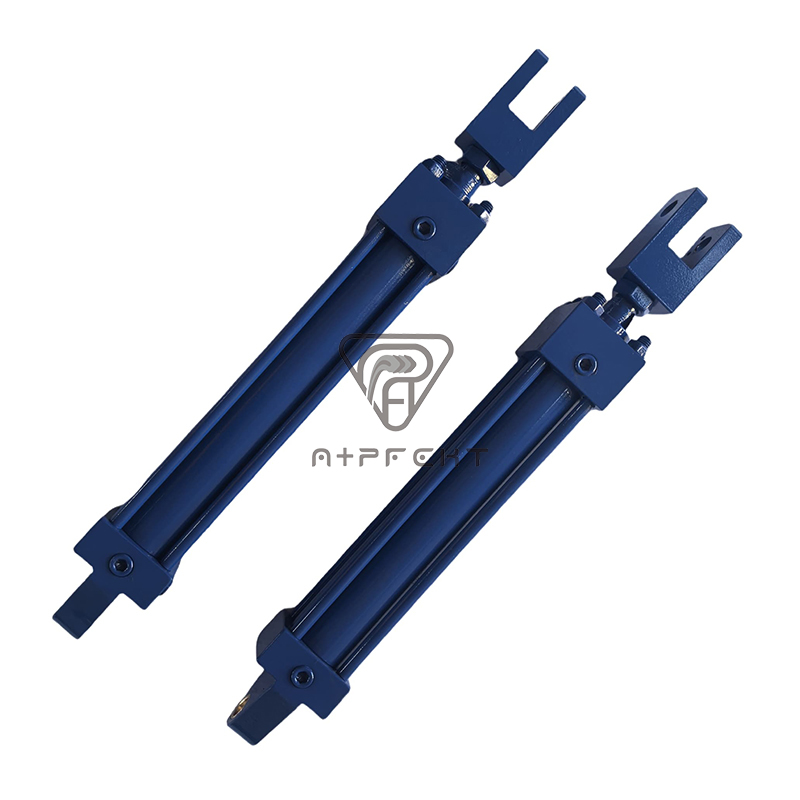

Double Ended Hydraulic Cylinder

Product Attributes

|

Model No. |

40 22.4-215 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Hydraulic lifting cylinders represent the backbone of industrial motion systems, delivering unparalleled linear force in the most demanding operating environments. Hydraulic cylinder for lifting platform, advanced sealing technologies with multi-stage wiper systems that prevent contamination while maintaining leak-free operation at pressures up to 700 bar in extreme-duty applications. Modern designs incorporate composite materials and surface treatments like plasma-sprayed ceramic coatings that triple service life in abrasive conditions. Hydraulic cylinder for lifting equipment now include AI-powered predictive algorithms that monitor seal wear patterns and fluid conditions in real-time, preventing 85% of potential failures before they occur.

The latest generation cylinders demonstrate remarkable versatility across emerging applications. In renewable energy, they precisely position 20-ton wind turbine blades during assembly with 0.01mm repeatability. Automated warehouses employ ultra-compact rodless models with integrated position feedback for high-speed parcel sorting. The aerospace industry utilizes titanium-alloy cylinders for aircraft landing gear that withstand 50,000+ stress cycles. Semiconductor manufacturing depends on cleanroom-certified versions with zero particulate emission for wafer handling robots.

Breakthrough innovations include self-healing hydraulic seals that automatically compensate for wear, and graphene-enhanced rods that reduce friction by 40%. Smart cylinders now feature wireless pressure and temperature sensors that transmit data via industrial iot networks, while energy-recovery systems capture and reuse 35% of kinetic energy during deceleration. These advancements cement hydraulic cylinders as irreplaceable components where extreme force, precision, and reliability converge - from deep-sea mining equipment to mars rover landing systems.

English

English  Español

Español