|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

CFR,CIF,EXW,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Port |

Shanghai, Guangzhou |

|

Model |

220 140-60 |

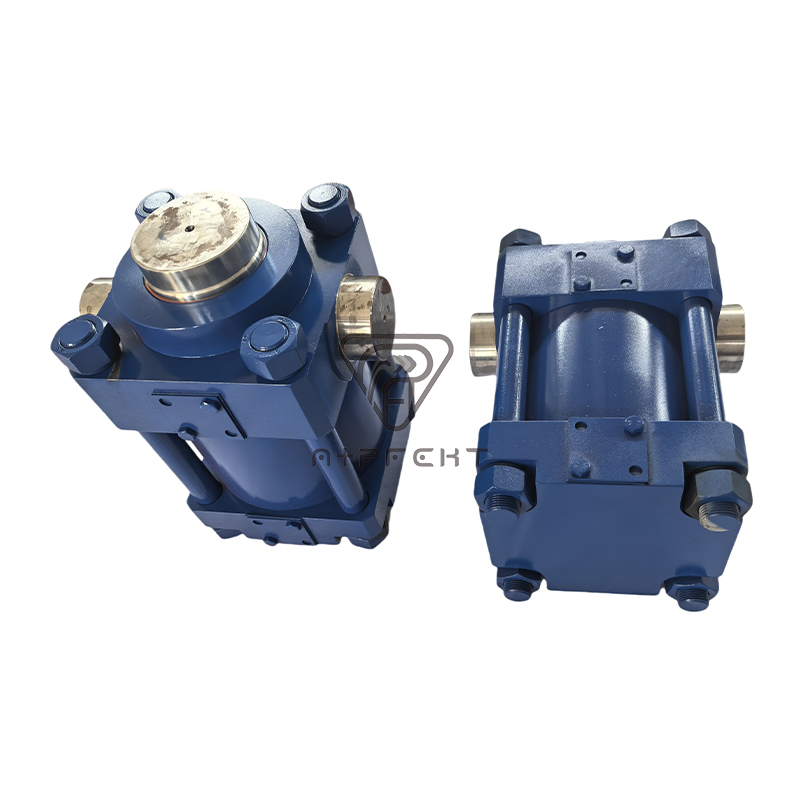

Industrial Hydraulic Pusher Cylinder

Product Attributes

|

Model No. |

220 140-60 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

|

Package Type |

Wooden package |

Bolt hydraulic cylinder is a robust and efficient actuator designed to deliver powerful linear force in various industrial applications. Commonly used in metal forming, pressing, molding, and material handling operations, industrial machinery hydraulic oil cylinder provides reliable and precise pushing motion, making it ideal for environments where high thrust and durability are required. Constructed with high-quality materials and advanced sealing systems, pushing hydraulic cylinders ensure long-term performance even under heavy loads and harsh working conditions.

Pull rod hydraulic cylinders are typically characterized by their strong structural design, incorporating heavy-duty tie rods and precision-machined components to withstand high pressure and repeated cycles. The cylinder’s bore size, stroke length, and mounting configuration can be customized to fit specific equipment and operational requirements. In addition, the hydraulic system provides smooth and controlled movement, enhancing operational safety and efficiency.

Pushing hydraulic cylinders are widely utilized in industries such as metallurgy, construction, automotive manufacturing, and general machinery. Their ability to generate substantial force with high accuracy makes them essential components for tasks like pressing, lifting, clamping, and ejecting materials. With options for both single-acting and double-acting designs, these cylinders can be tailored for specific applications, ensuring flexibility and optimal performance.

Overall, pushing hydraulic cylinders combine strength, reliability, and versatility, providing critical support for demanding industrial operations where consistent and efficient linear force is essential.

English

English  Español

Español