|

Payment Type |

T/T,L/C,D/P,Paypal |

|

Incoterm |

FOB,CIF,CFR,EXW,CIP,DDP,CPT |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Port |

shanghai |

|

Model |

180 125-180 |

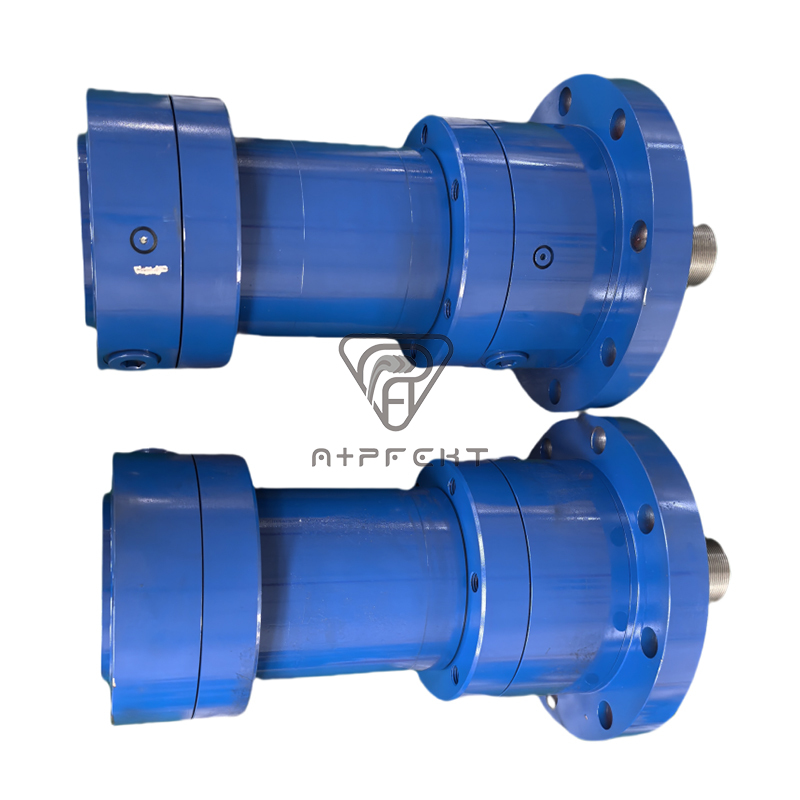

Customs Agricultural Hydraulic Cylinders

Product Attributes

|

Model No. |

180 125-180 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

|

Package Type |

Wooden package |

Differential hydraulic cylinders represent the workhorse of industrial motion control, delivering unparalleled linear force with robust simplicity. These mechanical muscles convert pressurized fluid into powerful, precisely controlled movement across countless applications. Engineered for durability, modern cylinders feature advanced materials like tungsten-carbide-coated rods and composite bearing surfaces that withstand abrasive contaminants while maintaining leak-free operation. Their modular architecture permits easy customization - from miniature 10mm bore units for delicate positioning to massive 1-meter diameter cylinders generating thousands of tons for metal forging.

The technologyx27s inherent advantages include instant torque availability at zero speed, making them ideal for heavy lifting applications like crane booms and hydraulic presses. Precision models achieve positioning repeatability within 0.01mm for machining applications, while heavy-duty variants operate reliably in punishing environments from arctic temperatures to steel mill heat. Smart cylinders now incorporate embedded sensors that monitor pressure, position, and temperature, enabling condition-based maintenance and integration with Industry 4.0 systems.

From mobile construction equipment to factory automation and renewable energy systems, engineering hydraulic oil cylinders provide the muscle for critical operations where reliability is non-negotiable. Molder hydraulic oil cylinder's ability to store energy in accumulators ensures continued operation during power outages, while proportional valve control enables infinitely variable speed and force adjustment. The combination of power density, environmental resilience, and precise controllability ensures hydraulic cylinders remain the premier solution for heavy linear motion applications worldwide.

English

English  Español

Español