|

Payment Type |

L/C,T/T,Paypal |

|

Incoterm |

FOB,CIF,EXW,CIP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Model |

100 56-585 |

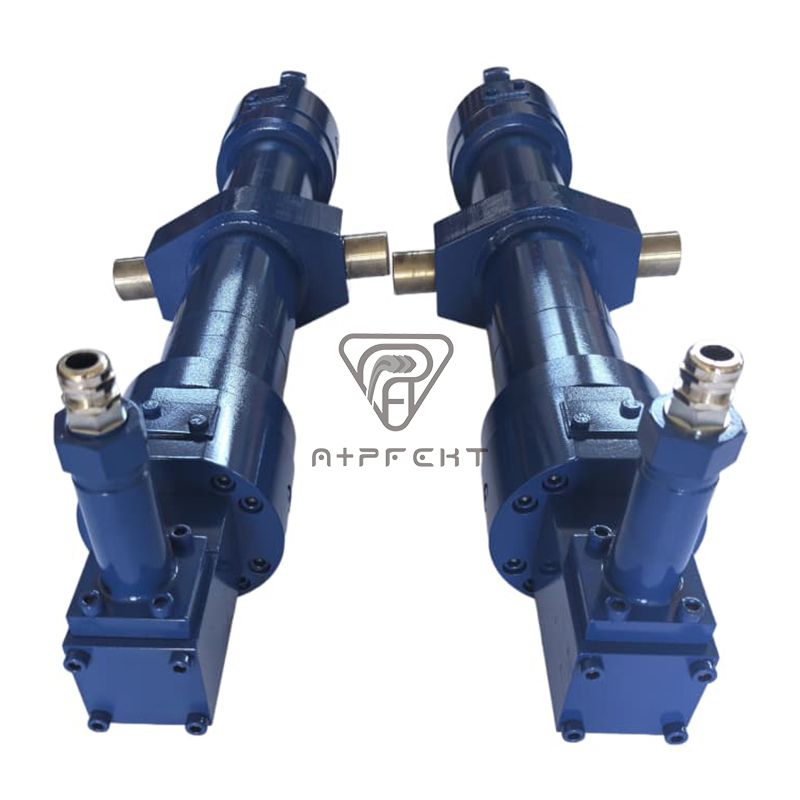

Hydraulic Cylinder with Sensor

Product Attributes

|

Model No. |

100 56-585 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

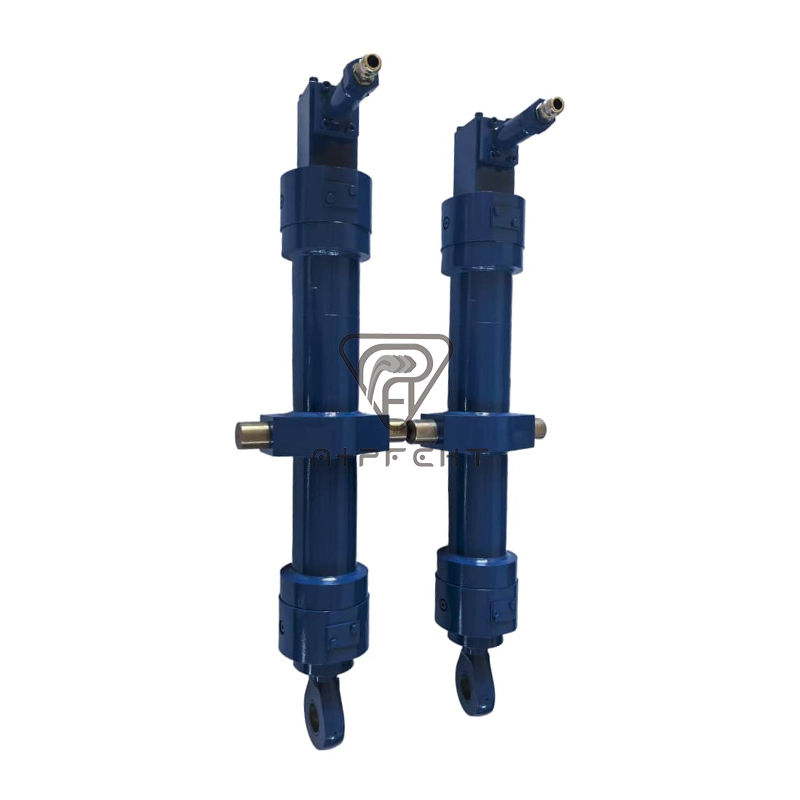

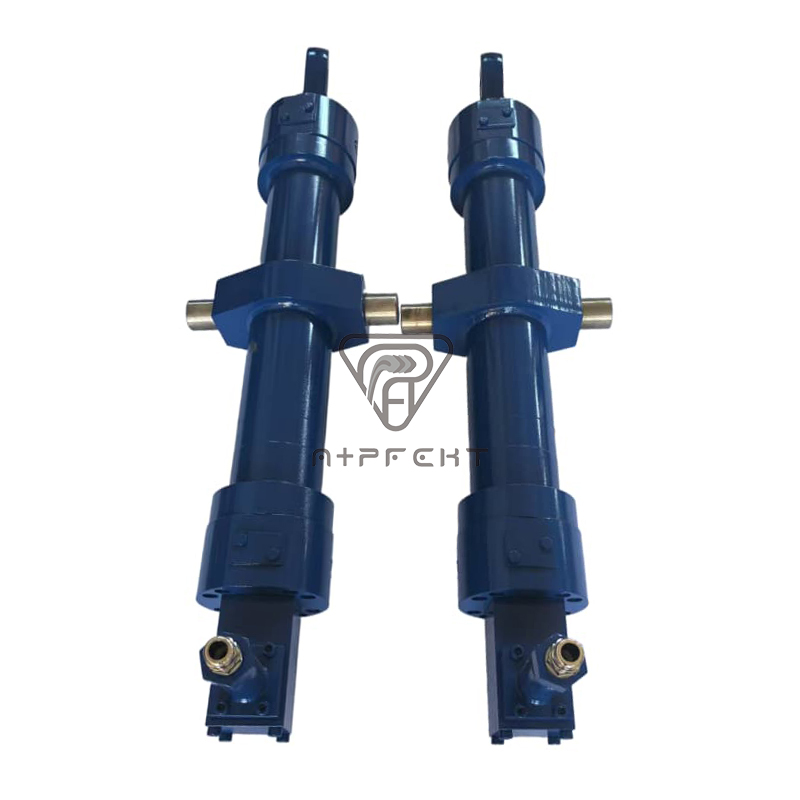

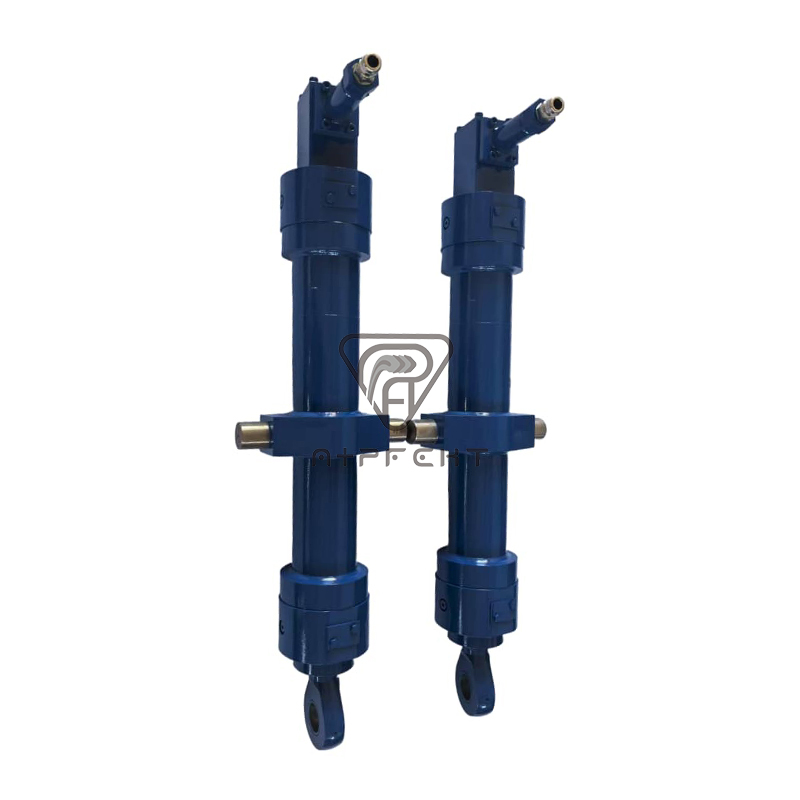

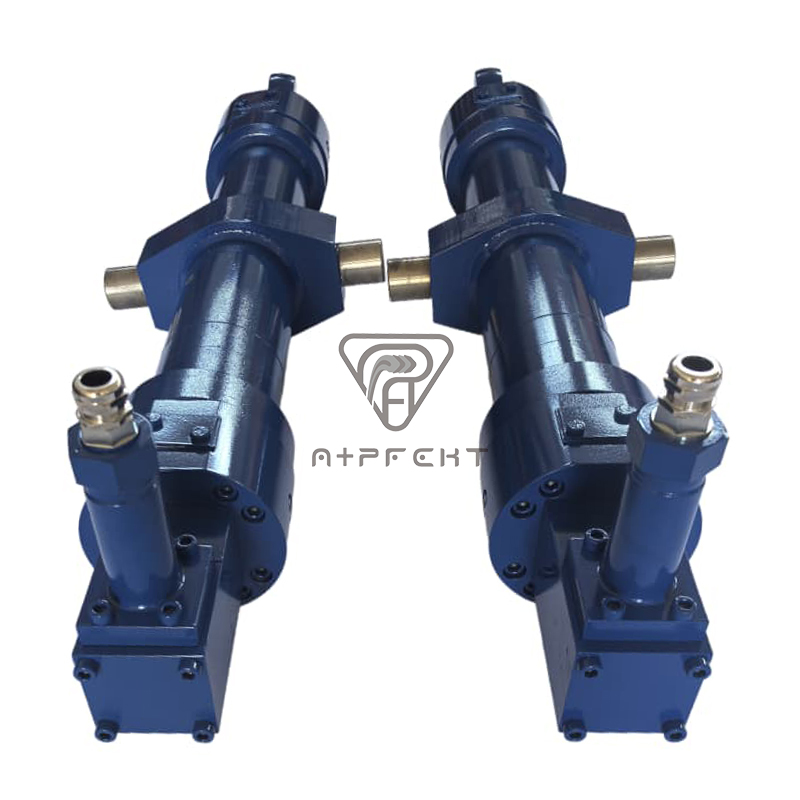

Differential hydraulic cylinders with a working pressure of 29MPa and a test pressure of 37MPa, equipped with sensors, has the characteristics of high pressure, high strength, and reliable sealing, and can achieve stable and accurate linear push-pull motion under harsh working conditions. The integrated sensor can provide real-time feedback on piston position, improve automation control and safety monitoring capabilities, and is widely used in applications such as construction machinery and industrial equipment that require high precision and reliability. An engineering hydraulic oil cylinder is an efficient and intelligent hydraulic transmission solution.

Molder hydraulic oil cylinder suitable for heavy-duty and automation scenarios that require high thrust, high precision, and real-time status feedback, it performs excellently in various high-end application fields such as engineering machinery, industrial equipment, automated production lines, metallurgy and mining.

As long as the selection is reasonable, the installation is standardized, and regular maintenance is carried out, the overall service life of such high-pressure, sensor-equipped hydraulic cylinders can reach 5-10 years or longer. Key components such as seals need to be replaced regularly according to wear to ensure long-term reliable operation.

English

English  Español

Español