|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CIF,EXW,CPT,CIP,DDP |

|

Min. Order |

1 Set/Sets |

|

Transportation |

Ocean,Land,Air |

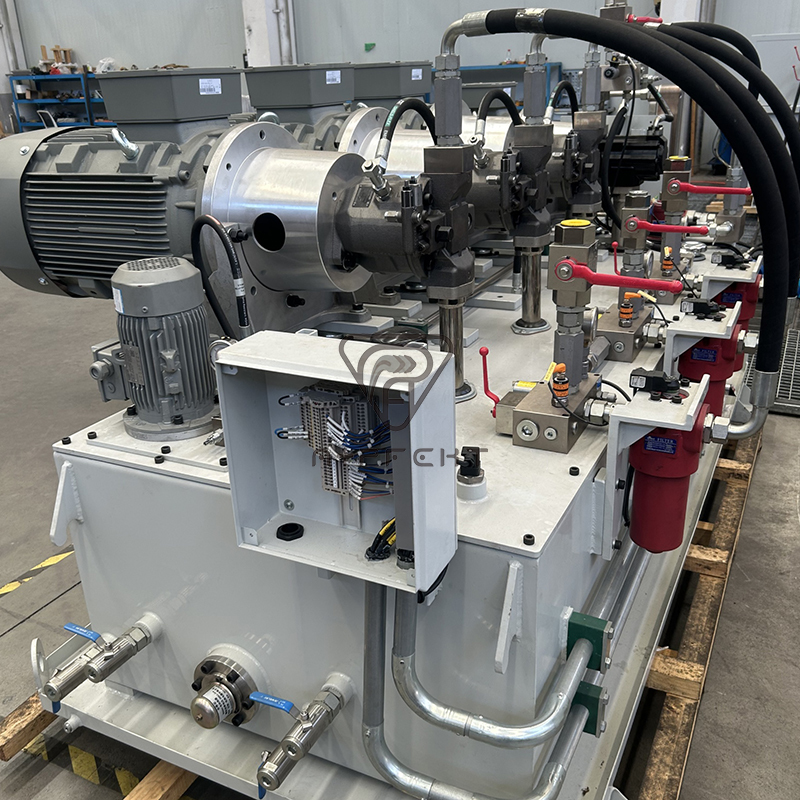

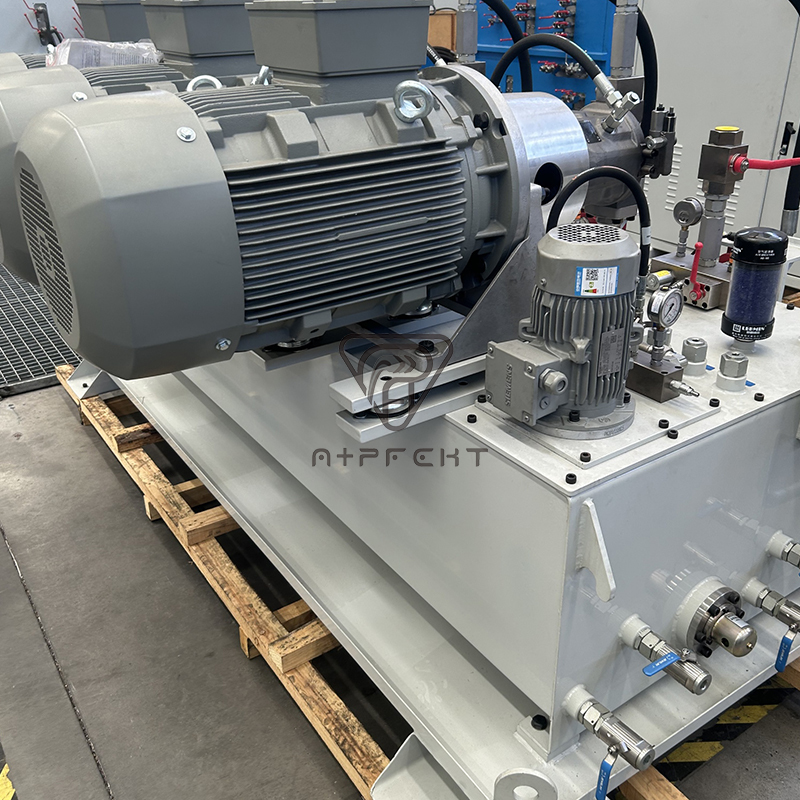

Electro Hydraulic Power Unit

Product Attributes

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Hydraulic systems serve as the backbone of modern industrial machinery, providing powerful and precise force transmission across countless applications. These systems consist of four fundamental components working in harmony: power units (pumps and motors generating 50-700 bar pressure), control elements (valves and regulators managing flow direction and force), actuators (cylinders converting pressure to linear motion and motors for rotation), and auxiliary components (reservoirs, filters, and coolers maintaining fluid integrity). The technology delivers unparalleled power density, with compact hydraulic cylinders generating forces exceeding 10,000 tons while maintaining micron-level positioning accuracy in servo-controlled systems.

Industrial applications span from massive forging presses shaping aircraft components to micro-positioning stages in semiconductor manufacturing. Construction equipment relies on hydraulic systems for excavator arms and crane operations, while agricultural machinery utilizes them for plow control and harvesting functions. The aerospace industry depends on hydraulic actuation for flight control surfaces, and automotive manufacturing employs these systems for precision stamping and assembly line automation. Emerging applications include renewable energy systems like wave power generators and wind turbine pitch control.

Modern hydraulic systems incorporate smart technologies including IoT-enabled predictive maintenance sensors that monitor fluid contamination, pressure transients, and component wear. Energy-efficient designs now recover up to 40% of kinetic energy during deceleration, while advanced filtration maintains fluid cleanliness to ISO 4406 14/11 standards. The systemsx27 unique combination of brute force capability, precise controllability, and environmental resilience ensures their continued dominance in applications where electrical systems cannot match their performance or reliability requirements.

English

English  Español

Español