|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CFR,CIF,EXW,CPT,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Air,Land,Ocean |

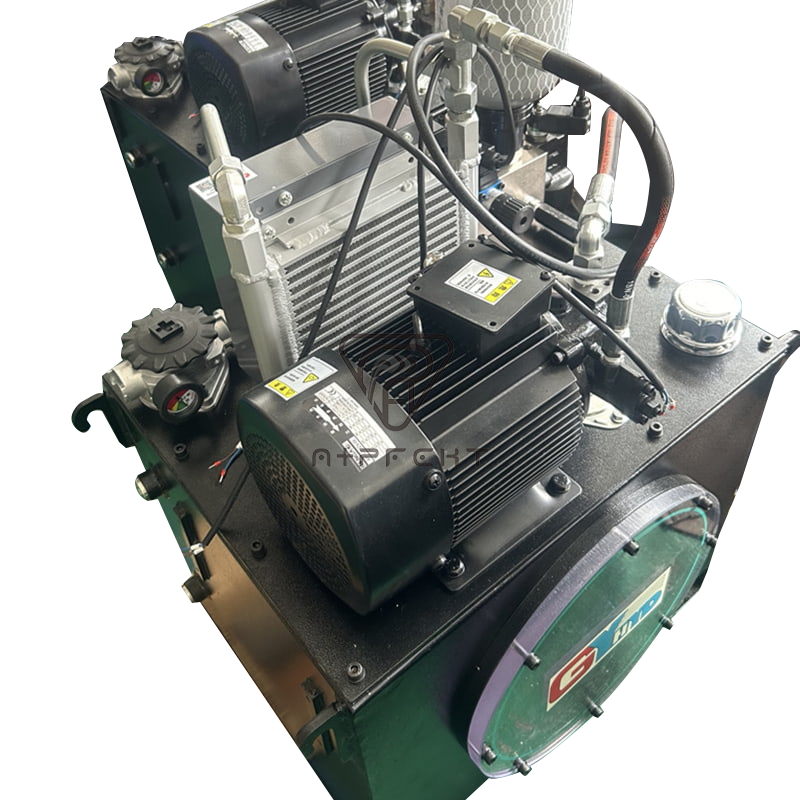

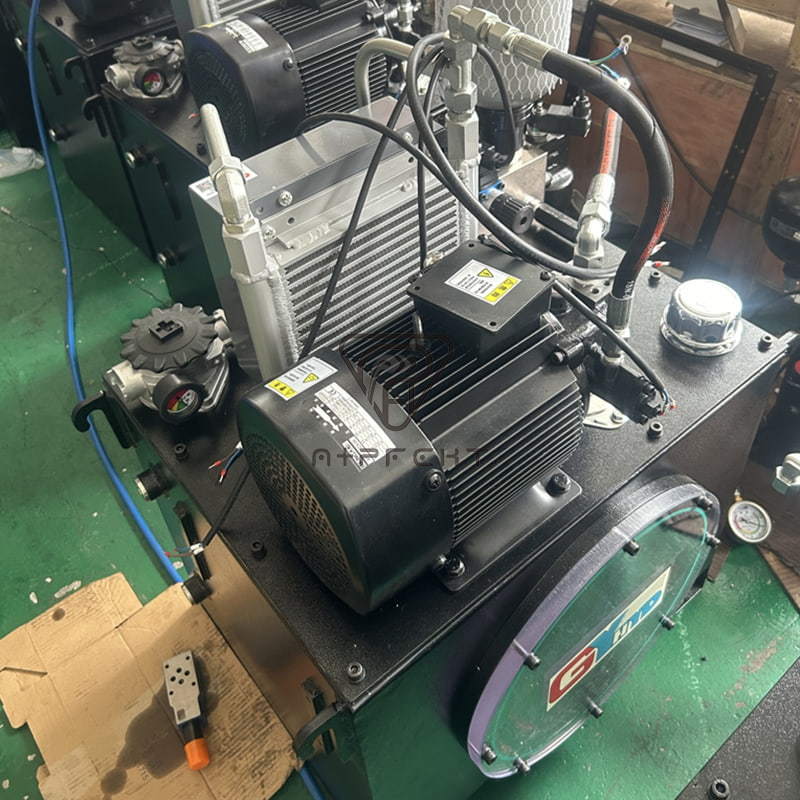

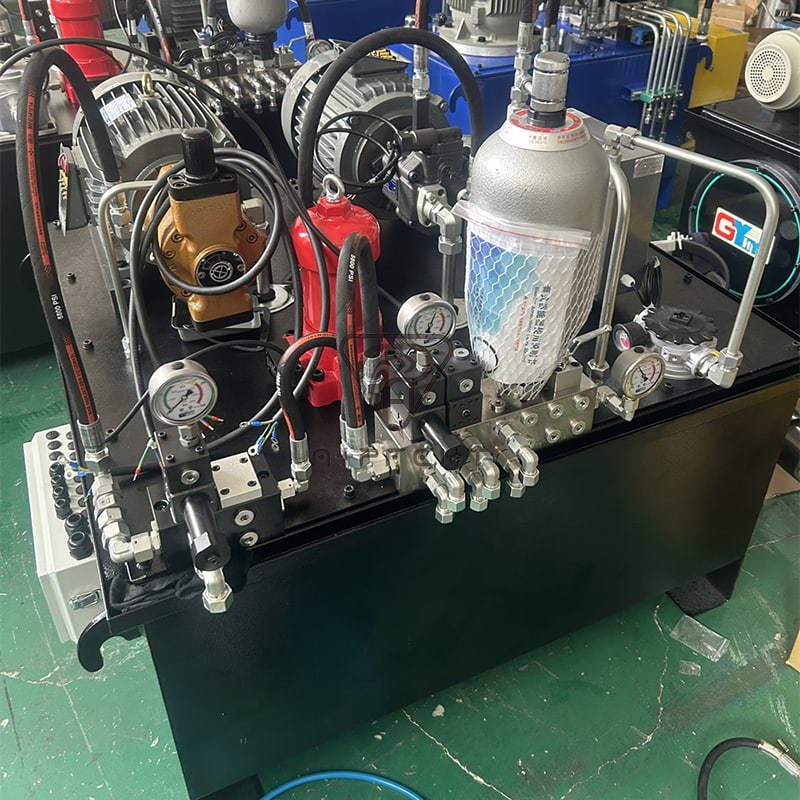

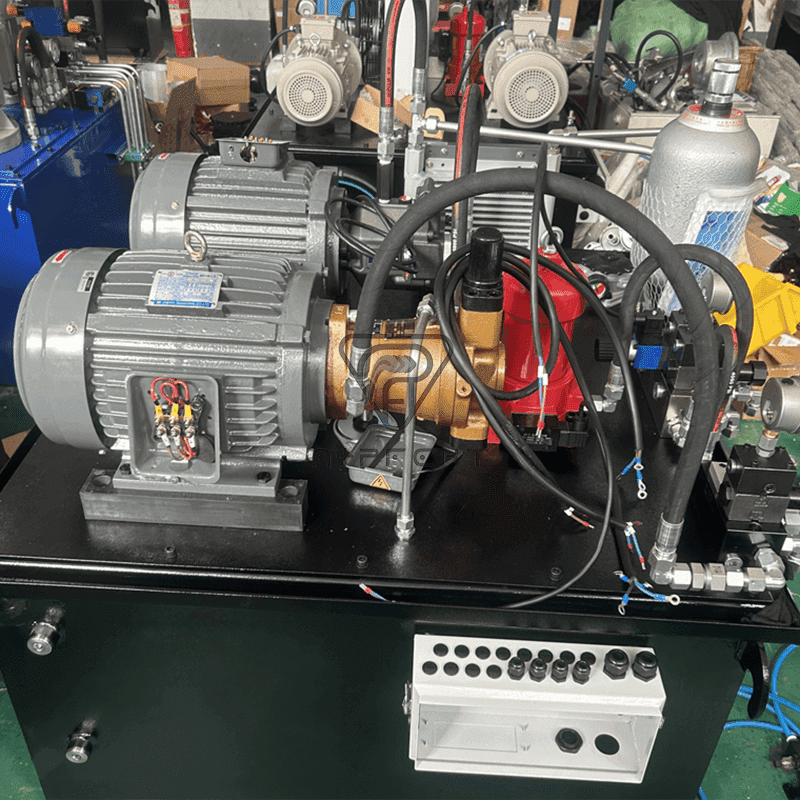

Servo Controlled Hydraulic Station

Product Attributes

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Odm, Oem |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

Machine tool gantry machining center hydraulic systems are engineered for high-precision, heavy-duty cutting operations, delivering exceptional stability and power density. These systems utilize servo-controlled proportional valves to achieve positioning accuracy within ±0.01mm, critical for aerospace and mold manufacturing applications. Advanced designs incorporate dual-pressure circuits - low-pressure high-flow for rapid traverse (up to 30m/min) and high-pressure low-flow for precision finishing cuts (0.1-5m/min). The hydraulic balancing systems for Z-axis rams employ fuzzy PID-controlled proportional relief valves to dynamically compensate for tool weight variations up to 5,000kg, preventing servo motor overload and minimizing ball screw wear.

Key applications include titanium aircraft structural component machining where the systems maintain 20-ton cutting forces with vibration damping below 0.5μm, and large-die manufacturing requiring uninterrupted 72-hour operation cycles. Modern systems integrate IoT-enabled predictive maintenance, monitoring parameters like fluid particulate count and valve spool wear to prevent unplanned downtime. Emerging innovations include water-based hydraulics for cleanroom environments, eliminating oil contamination risks in medical device machining. The systemsx27 ability to combine brute force (50+ ton axis drives) with sub-micron precision makes them indispensable for next-generation smart manufacturing.

English

English  Español

Español