|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

CIF,EXW,FOB,CIP,DDP,CPT |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Air |

|

Port |

shanghai |

|

Model |

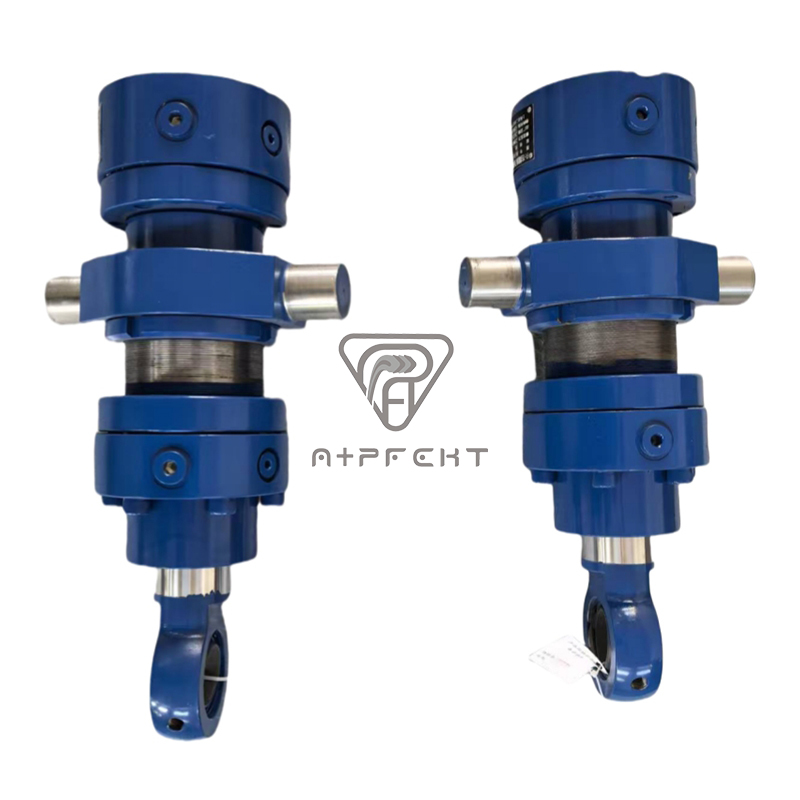

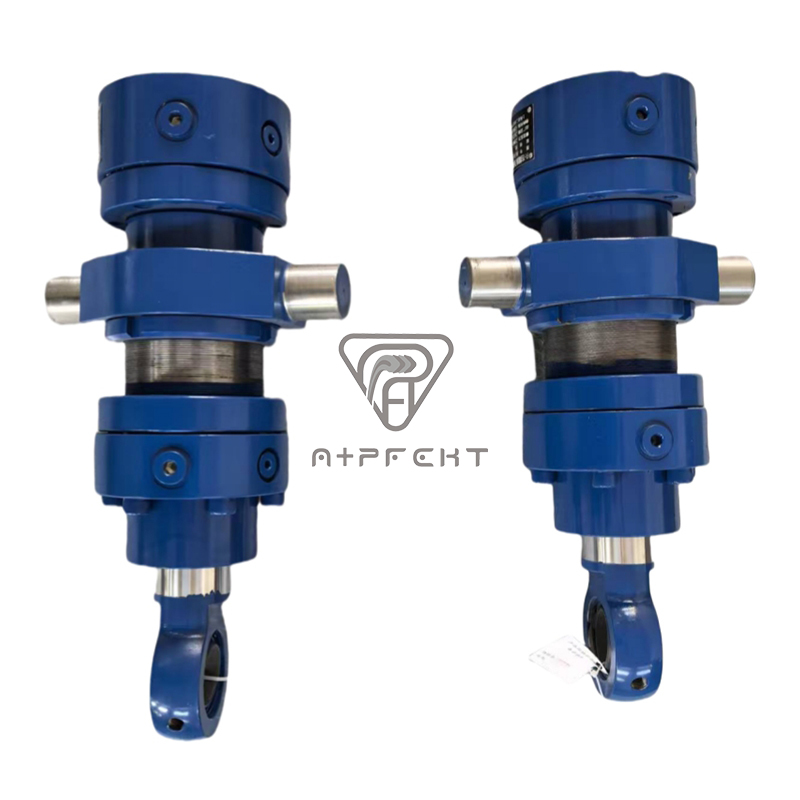

80 56-70 |

Backup Roll Locking Cylinder

Product Attributes

|

Model No. |

80 56-70 |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support |

|

Support Customization |

Oem, Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

|

Package Type |

Wooden package |

Backup roll locking cylinder and mill door clamping cylinder provide modern rolling mills with significant operational and safety benefits due to sophisticated hydraulics. Locking Hydraulic Cylinder of this type usually 50-200 metric tons of clamping force to counter axial slippage of backup roll chocks during rolling operations and prevents axial displacement of backup roll chocks during rolling operations, even when rolling loads exceed 10,000 kN. These cylinders enable rapid roll changes in less than 15 minutes by performing three functions in one, integrated design: interlock rolls for positioning, mill door locking, and provide safety overload protection. Achieving ±0.5mm roll positioning accuracy and several hardened steel anti-friction bearings ensure long life with temperatures and pressures typical in hot strip mills. Fluorocarbon seals, rated for 200°C and capable of withstanding 200°C ensure reliable operation in harsh environments.

Hydraulic cylinders for sale, accidental release is prevented through a key innovation which encompasses both hydraulic pressure holding (using pilot-operated check valves) and mechanical locking features. The accumulated response time for Industrial Locking Cylinders is optimised to over three seconds for a full stroke which satisfies the roll change automation sequencing needs. During maintenance, standardised SAE/ISO flange connections, mostly Code 62 or 61, are easy to disassemble for access. Integrated position sensors and pressure transducers allow for real-time data monitoring through the mill’s PLC system which is lead to the mill. In the presence of acidic coolants, cold rolling applications are served through special variants featuring stainless steel rods and HVOF corrosion-resistant coatings which extend the service life.

English

English  Español

Español