|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CIF,EXW,CPT,CIP,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Port |

s,h,a |

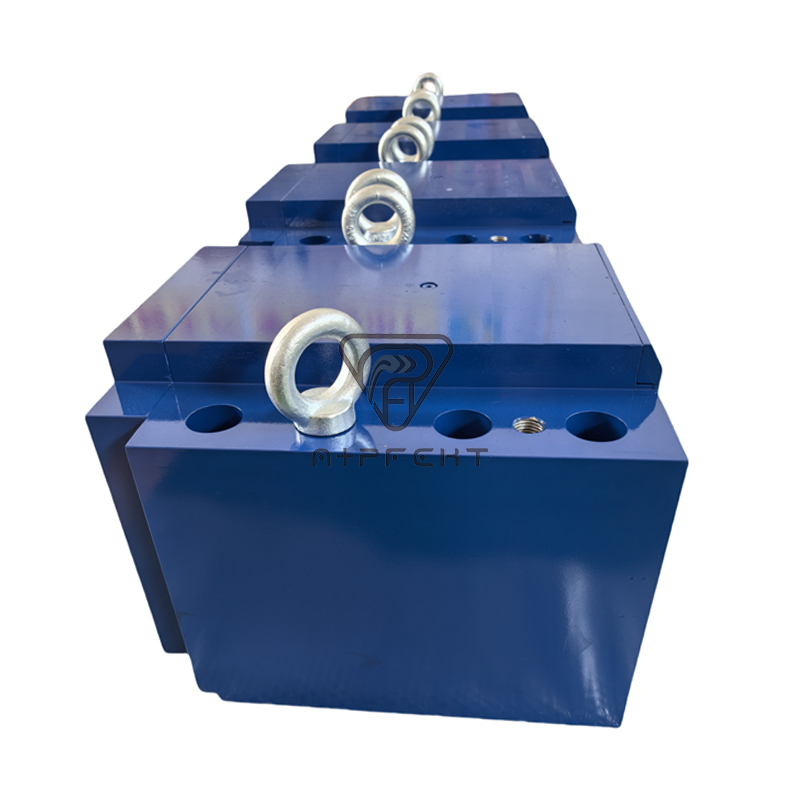

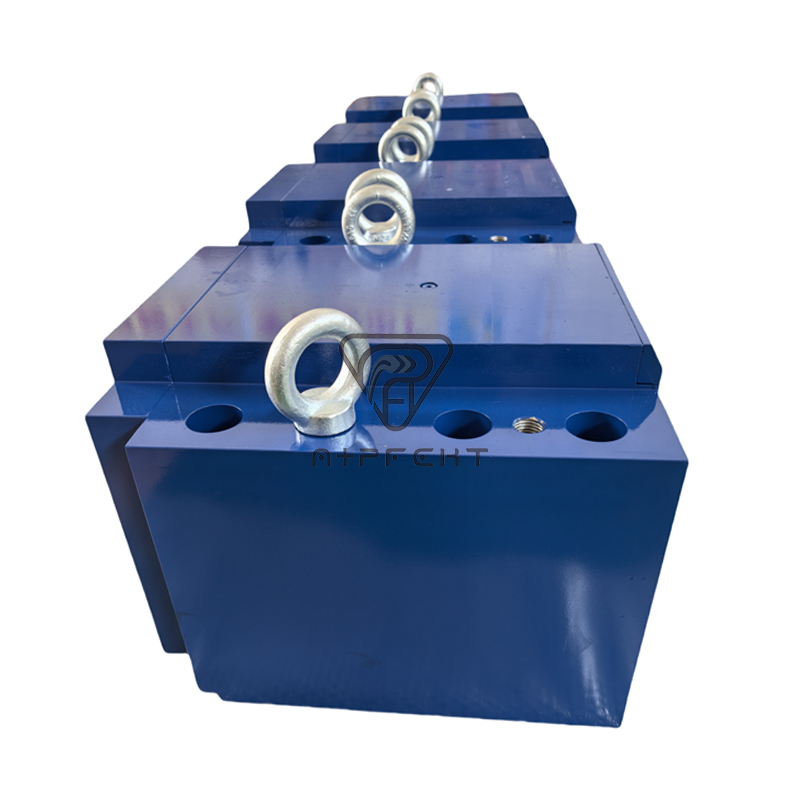

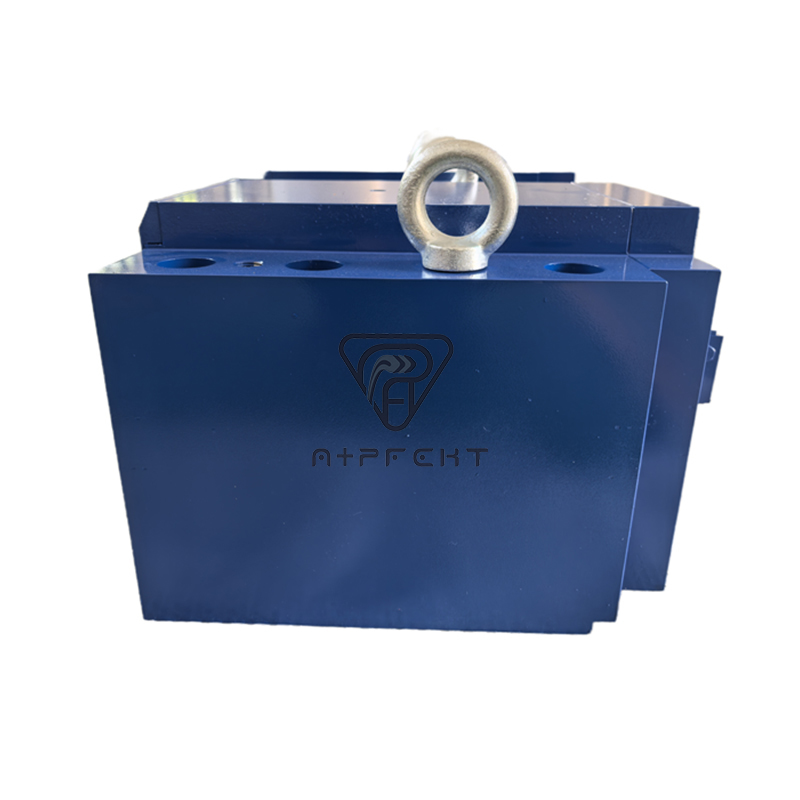

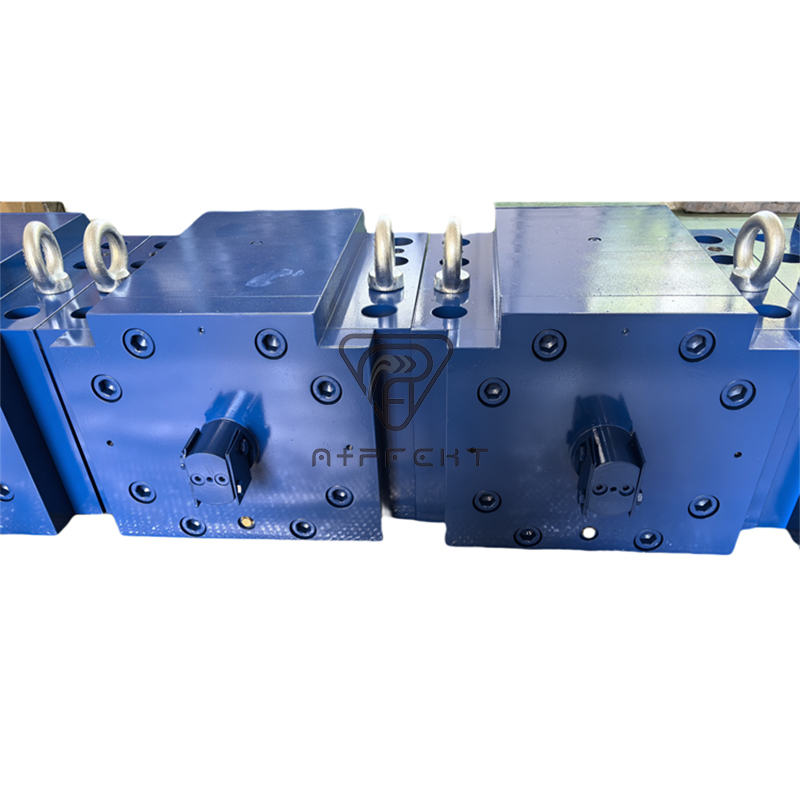

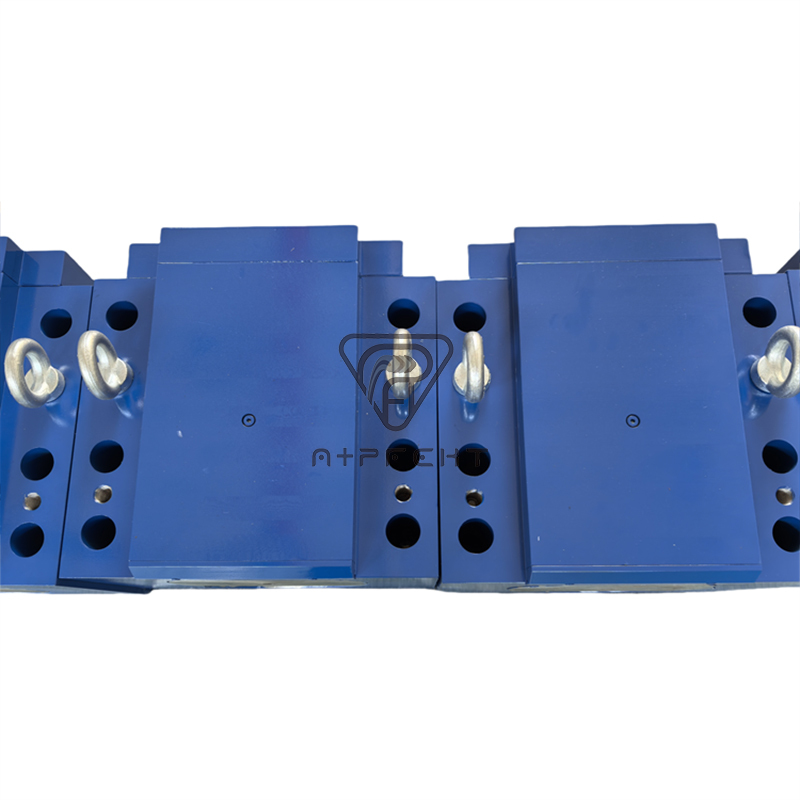

Heavy-duty Locking hydraulic Cylinder

Product Attributes

|

Model No. |

200 100-75 |

|

Brand |

NOK Hydraulic |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

|

Package Type |

Wooden package |

Locking hydraulic cylinders deliver unparalleled safety and precision across industrial applications through their innovative pressure-sustaining technology. Hydraulic cylinders for sale maintain precise positioning without continuous energy input, utilizing either mechanical interlock systems (wedge, tooth, or collet-type) or hydraulic pressure-holding circuits to secure loads from 1 to 1,000 metric tons. Industrial locking cylinders' fundamental advantage lies in eliminating positional drift - critical for precision applications like aerospace component machining, where even 0.005mm movement can compromise tolerances. The self-locking mechanism reduces hydraulic system energy consumption by 25-40% compared to conventional constant-pressure systems while providing failsafe operation during power outages or pressure loss.

Manufactured with hardened alloy steel components and multi-layered sealing systems, these cylinders withstand extreme conditions, including continuous operation at 300°c in die casting machines or sub-zero temperatures in arctic oil rigs. Specialized versions feature corrosion-resistant coatings for offshore applications, cleanroom-certified designs for semiconductor manufacturing, and explosion-proof configurations for petrochemical plants. Advanced models incorporate real-time condition monitoring through integrated position sensors and pressure transducers, enabling predictive maintenance by tracking seal wear and lock engagement timing.

English

English  Español

Español