|

Payment Type |

L/C,T/T,D/P,Paypal |

|

Incoterm |

FOB,CIF,EXW,CPT,DDP |

|

Min. Order |

1 Piece/Pieces |

|

Transportation |

Ocean,Land,Air |

|

Port |

shanghai |

|

Model |

Locking hydraulic cyclinder |

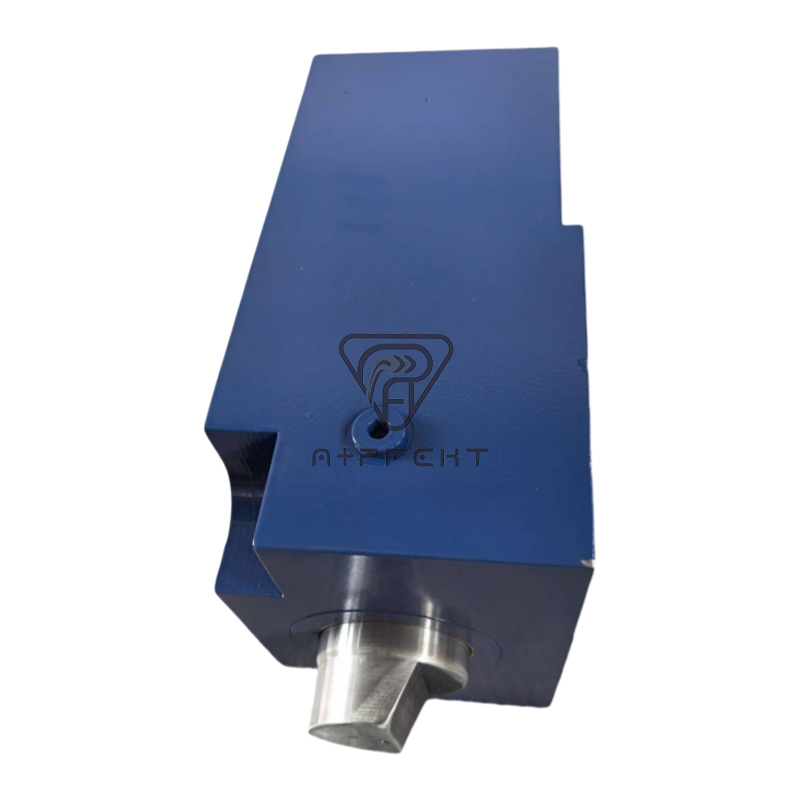

Locking Hydraulic Oil Cylinder

Product Attributes

|

Model No. |

Locking hydraulic cyclinder |

|

Brand |

NOK Hydraulic |

|

Warranty Period |

1.5 Years |

|

Out-of-warranty Service |

Online Support |

|

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets) |

Indonesia |

|

Showroom Location (in Which Countries Are There Sample Rooms Overseas) |

None |

|

Place Of Origin |

China |

|

Service System |

Online Support, Video Technical Support |

|

Support Customization |

Odm |

Packaging & Delivery

|

Selling Units |

Piece/Pieces |

|

Package Type |

Wooden package |

Locking hydraulic cylinders provide critical safety and operational advantages across industrial applications by maintaining position without continuous hydraulic pressure. Hydraulic cylinders for sale, specialized actuators deliver secure clamping forces from 5 to 500 tons through mechanical or hydraulic locking mechanisms, ensuring zero displacement even during power loss or system pressure drops. Their self-locking design eliminates the need for constant energy input, reducing hydraulic system load and cutting energy consumption by up to 30% compared to conventional holding systems. The industrial locking cylinders' precision-ground components and multi-stage sealing systems achieve positioning repeatability within ±0.01mm, essential for precision machining fixtures and aerospace assembly jigs. Heavy-duty versions feature tungsten-carbide-coated locking surfaces that withstand over 1 million cycles in high-vibration environments like metal stamping presses.

Advanced models incorporate fail-safe dual locking systems combining hydraulic holding with mechanical interlocks (typically wedge or tooth-type), providing redundant protection for critical applications such as wind turbine maintenance or nuclear fuel handling. The cylindersx27' compact designs save up to 40% space versus equivalent motorized clamping systems while offering faster response times (<100ms for full engagement). Specialized variants include corrosion-resistant stainless steel constructions for marine applications, high-temperature versions for foundry equipment (operating continuously at 250°c), and cleanroom-optimized models for semiconductor manufacturing.

Integrated position feedback sensors and IoT-enabled condition monitoring allow real-time tracking of lock status and wear indicators, enabling predictive maintenance. These cylinders significantly improve safety in press brakes and injection molding machines by preventing accidental release during operations, while their zero-leakage designs maintain clamping force for extended periods (72+ hours in some applications). The combination of mechanical reliability, energy efficiency, and smart monitoring capabilities makes locking cylinders indispensable for modern manufacturing, with typical roi periods under 12 months due to reduced downtime and energy savings.

English

English  Español

Español